GaugeHow Business Plan

Empower Your Students & Engineering Teams With Real Mechanical Skills

GaugeHow® offers 40+ industry-focused, self-paced courses designed to build hands-on engineering skills. Whether you’re a college, training institute, or manufacturing company—your learners get modern technical skills, job-ready capabilities, and measurable outcomes.

Three Tracks. One Mechanical Career Path

Learning From Design to Manufacturing

Most people learn mechanical skills in random fragments. Here, the Mechanical Engineering courses are grouped into three tracks that mirror real work: CAD courses for design output, FEA and CFD simulation for validation, and an Industry 4.0 course track for modern factories.

Learn 40+ Mech Tools

Course Categories

Unlock Mechanical Engineering Career Paths

On GaugeHow, the Mechanical Engineering Courses are grouped by real job tracks, so you can pick the skills recruiters expect for design, simulation, manufacturing, quality, automation, and smart factories.

Core Mechanical Fundamentals

Start with the fundamentals that make every advanced tool easier: drawings, GD&T basics, and manufacturing understanding.

Engineering Drawing

GD&T

Basics of IC Engine

Manufacturing Technologies

Basics of Material Handling

CAD Courses: Product Design & Modeling

Build design output that teams can manufacture: 2D drafting, 3D modeling, assemblies, and drawings.

AutoCAD

SolidWorks 2024

CATIA V5

Siemens NX

PTC Creo

Fusion 360

Simulation using SpaceClaim

FreeCAD

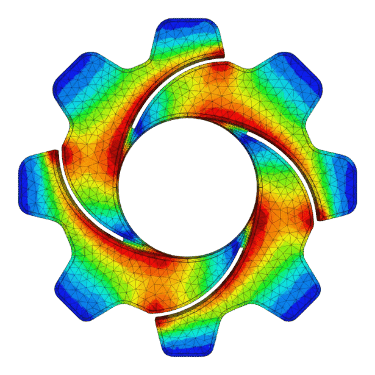

CAE Simulation: FEA, CFD & Multiphysics

Validate before you build. This track covers FEA and CFD simulation workflows used in CAE and R&D teams.

Basics of FEA with ANSYS

ABAQUS CAE

ANSYS Fluent

Autodesk CFD

OpenFOAM for CFD

EV Battery Cooling

COMSOL Multiphysics

PLC Programming, Automation & Robotics

Add control and automation skills that translate to real plant and robotics workflows, not just coding exercises.

MATLAB Programming

Python for Mechanical Engineers & Robotics

PLC Programming and Automation

Introduction to Mechatronics (Robotics)

C and C++ for Mechanical Engineers

Quality, Metrology & Lean Manufacturing

Run stable production and prove quality with measurement discipline, root-cause thinking, and lean tools.

CNC Programming

Basics of 6 Sigma

TQM, Kaizen and 5S System

Lean Manufacturing Tools

7 QC Tools

Engineering Metrology & 3D Measurement

Uncertainty Measurement and of ISO 17025:2017

Industry 4.0 Course: Smart Manufacturing

Move from classical mechanical to factory tech: data, connectivity, and digital manufacturing concepts used in modern plants.

Introduction to Industry 4.0

3D Printing (Additive Manufacturing) for Industry 4.0

Digital Twins

Industrial Internet of Things (IIoT)

Basics of Digital Manufacturing

Smart Materials Science

Material Informatics

4.4/5 (Average of 1500+ Ratings)

Trusted by 23500+ learners

Faq Hub

Still Have Questions?

Contact Us, We are happy to help you

What is included in GaugeHow for colleges?

How fast can we onboard a student batch?

Do students get certificates, and can they be verified?

Is the program suitable for placement preparation?

What support is available if students have doubts?

Will I get a certificate when I finish?

What is the Refund policy?

What is the validity of Business Plans?