In today’s world, where precision is crucial, Digital Metrology has emerged as a game-changer, quietly transforming the way we measure, analyze, and understand the physical world around us.

This revolutionary field goes beyond the traditional tape measures and calipers, delving into the realm of digital technology to enhance accuracy, efficiency, and reliability.

In this blog, we’ll explore the intricacies of Digital Metrology, including its applications, IIoT integration, and its role in the Industry 4.0 and 5.0 landscape.

Understanding Digital Metrology:

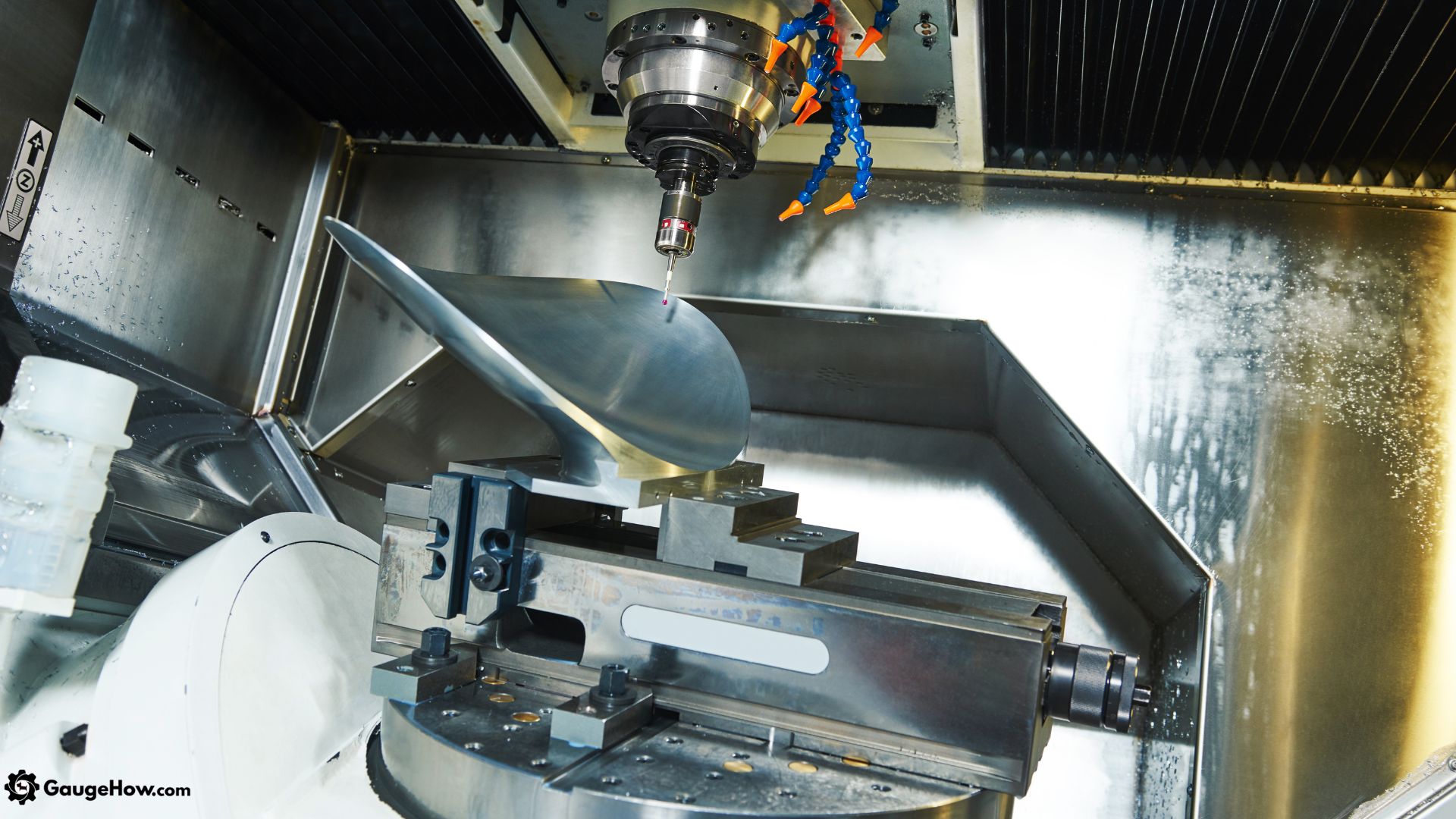

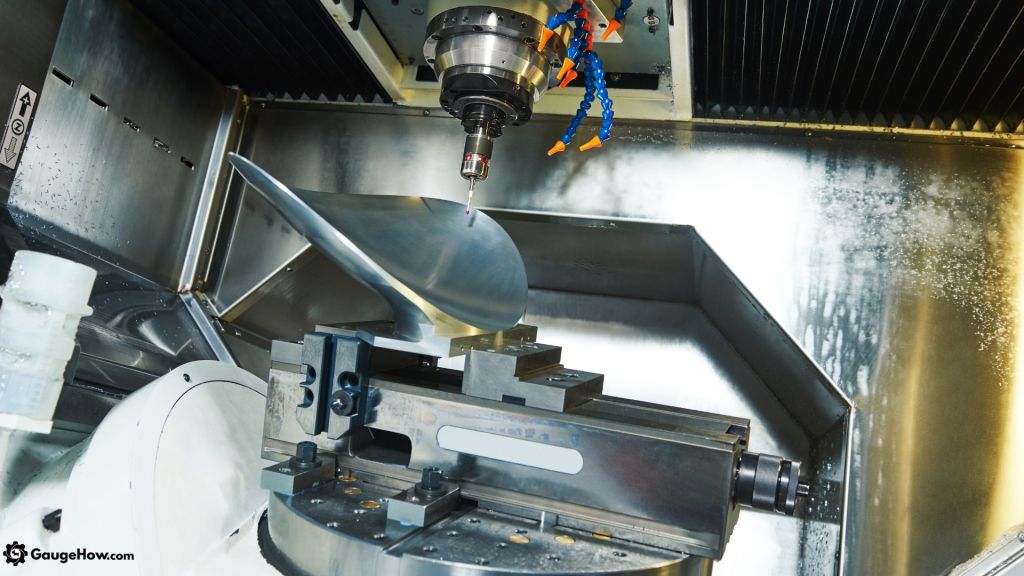

At its core, Digital Metrology is the science of measurement in the digital realm.

It involves using advanced technologies like lasers, sensors, and computer algorithms to precisely quantify physical dimensions and characteristics.

This shift from analog to digital methods brings unprecedented levels of accuracy, repeatability, and speed to the world of metrology.

IIoT Integration in Instruments:

The Industrial Internet of Things (IIoT) plays a pivotal role in the evolution of Digital Metrology.

By integrating sensors and devices with the power of connectivity, instruments become intelligent entities that can communicate, share data, and make informed decisions.

In the context of Digital Metrology, this means real-time monitoring of measurements, predictive maintenance, and seamless collaboration between various measurement devices.

Imagine a manufacturing floor where measurement instruments are not isolated entities but interconnected nodes forming a web of data.

This connectivity allows for a more holistic understanding of the production process, identifying potential issues before they escalate and optimizing overall efficiency.

Industry 4.0: Transforming Production Processes:

The marriage of Digital Metrology and Industry 4.0 signifies a paradigm shift in manufacturing.

Industry 4.0, characterized by the integration of smart technologies into the production process, leverages Digital Metrology to enhance quality control, reduce waste, and increase production speed.

In a smart factory, Digital Metrology ensures that each component is precisely measured, contributing to the creation of a digital twin – a virtual replica of the physical product.

This digital twin facilitates constant monitoring and analysis, enabling manufacturers to make data-driven decisions in real-time.

Industry 5.0: Human-Centric Evolution:

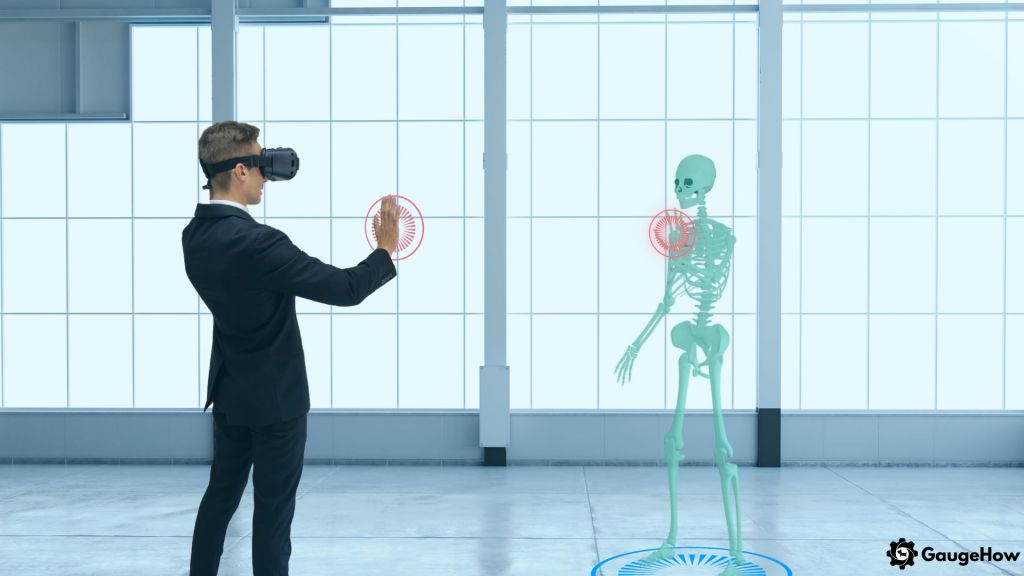

In the era of Industry 5.0, human collaboration takes center stage. Here, Digital Metrology not only serves the purpose of precision but also fosters seamless collaboration between humans and machines.

Measurement instruments become tools that empower workers, providing them with accurate data to make informed decisions and enhance their problem-solving capabilities.

Moreover, Industry 5.0 emphasizes the importance of customization and flexibility.

Digital Metrology, with its ability to provide highly detailed and tailored measurements, aligns perfectly with this vision of personalized and adaptive manufacturing processes.

As we continue to embrace the digital age, Digital Metrology stands as a beacon of innovation, guiding us toward a more accurate and connected world.