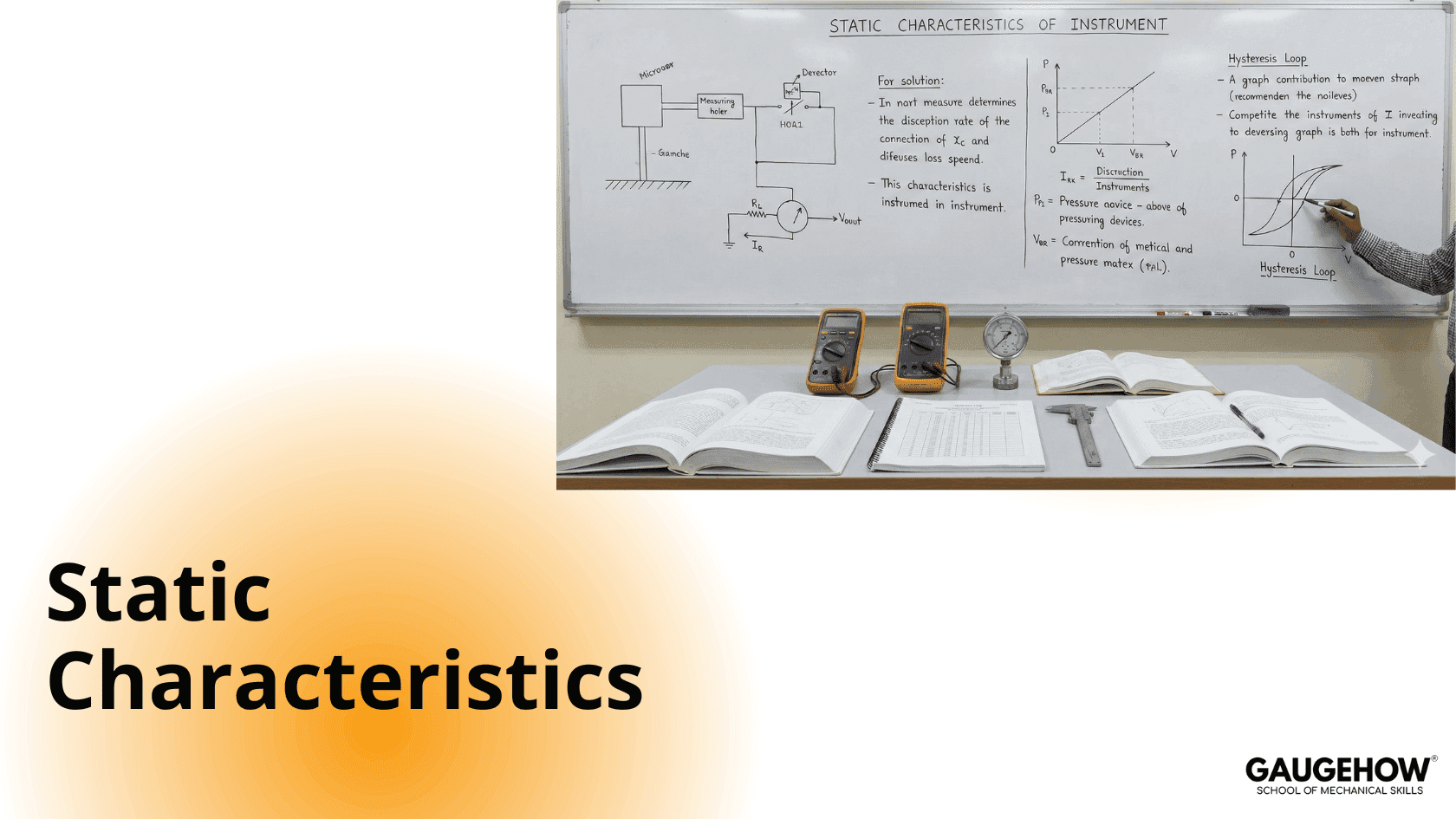

Static Characteristics

Dec 13, 2025

Performance Characteristics of Measuring Instruments

The performance characteristics of measuring instruments are broadly classified into two types:

Static characteristics

Dynamic characteristics

Static characteristics are used to evaluate instruments that measure quantities which are constant or vary slowly with time.

The important static characteristics are:

Accuracy

Sensitivity

Precision

Linearity

Resolution

Repeatability

Range

Tolerance

Hysteresis

Static Characteristics (Detailed Explanation)

1. Accuracy

Accuracy is the degree of closeness of the measured value to the true or actual value.

It is always expressed relative to the true value.

2. Sensitivity

Sensitivity is the ability of an instrument to detect small changes in the measured quantity.

Mathematically, it is defined as the ratio of change in output to the change in input:

Sensitivity=ΔOutputΔInput\text{Sensitivity} = \frac{\Delta \text{Output}}{\Delta \text{Input}}Sensitivity=ΔInputΔOutput

3. Precision

Precision refers to the degree of closeness of repeated measurements to each other, irrespective of the true value.

An instrument is said to be precise if it produces nearly identical readings for repeated measurements under the same conditions.

4. Linearity

Linearity is the ability of an instrument to produce output that is directly proportional to the input.

An instrument is considered linear if:

Equal increments in input produce equal increments in output

The input–output relationship follows a straight line over the specified range

5. Resolution

Resolution is the smallest change in input quantity that produces a detectable change in the output.

Small changes in input that do not affect the output continue until a threshold value is reached. This minimum detectable change is called the resolution.

6. Repeatability

Repeatability defines the ability of an instrument to produce the same output for the same input, when measurements are repeated under identical conditions.

7. Range

Range is the minimum and maximum values of the measured quantity for which the instrument operates satisfactorily.

Range=Maximum value−Minimum value\text{Range} = \text{Maximum value} - \text{Minimum value}Range=Maximum value−Minimum value

8. Tolerance

Tolerance is the maximum permissible error allowed in a measurement.

It is specified as a limit within which the measured value must lie to be considered acceptable.

9. Hysteresis

Hysteresis is the phenomenon where an instrument shows different output values for the same input, depending on whether the input is increasing (loading) or decreasing (unloading).

Mechanical Engineering Courses That Industry Actually Uses

Learn Tools of Design & CAD, Analysis & Simulation, Automation & Robotics, and Industry 4.0 used in modern factories.

Join 40+ Mech Courses like GD&T, Siemens NX, SolidWorks, CATIA V5, AutoCAD, ANSYS (FEA & Fluent), ABAQUS, Creo, Fusion 360, CNC Programming, Digital Twins, Python for Mechanical, and Industry 4.0.

Our Courses

Complete Course Library

Access to 40+ courses covering various fields like Design, Simulation, Quality, Manufacturing, Robotics, and more.