Dial Indicator (Plunger Dial Gauge)

Dec 13, 2025

Deepak S Choudhary

A dial indicator, also known as a plunger dial gauge, is one of the simplest and most widely used mechanical comparators.

The primary use of a plunger dial gauge is to compare a workpiece against a master or reference standard, rather than measuring absolute dimensions.

Least Count of Dial Indicator

A plunger dial gauge is commonly available in:

10 mm range with a least count of 0.01 mm

1 mm range with a least count of 0.001 mm

The selection depends on the application, required accuracy, and precision of measurement.

As the contact point moves upward or downward, the internal mechanism converts this movement into rotation of the pointer, which is displayed on the dial.

Dial indicators are also available with a large dial diameter for easy and clear reading.

Additional Features

Back plunger dial indicators are used when rear contact measurement is required

Digital dial indicators provide higher accuracy and easier reading than analog types

Dial indicators are available with different contact points based on application

Interchangeable back covers are available for various mounting situations

Colour caps and limit markers help identify tolerance limits

Precautions

The user should avoid:

Sudden contact with the workpiece

Over-tightening of contact points

Applying side pressure on the plunger

Lever Dial Gauge (Test Indicator)

A lever dial gauge, also known as a test indicator, is used for highly sensitive contact measurements.

Unlike a plunger dial gauge, it uses a lever-type contact mechanism, making it lighter and smaller.

Measuring Range and Least Count

Typical measuring range: 0.80 mm

Special designs: up to 2 mm

Common least count: 0.01 mm

High-precision models: 0.001 mm (range 0–1 mm)

These specifications apply to dial-type test indicators. For higher accuracy, digital test indicators are preferred.

Digital indicators offer better accuracy but are costly and require careful handling and maintenance.

How to Read a Lever Dial Gauge

Measurement using a lever dial gauge is straightforward:

As the lever moves, the internal mechanism transmits motion to the indicator

The dial shows the relative deviation from the reference

The same precautions apply: avoid shock, side load, and excessive force

Applications of Lever Dial Gauge

Lever dial gauges are commonly used to measure:

Height variation

Flatness

Roundness

Runout

They are often used in combination with:

Vernier height gauges

Digital height gauges

This ensures consistent measuring force.

Lever dial gauges are widely used in:

Manufacturing industries

Metrology laboratories

Tool rooms and workshops

Popular manufacturers include Mitutoyo, Mahr, and Baker, known for precision and reliability.

Dial Thickness Gauge

A dial thickness gauge is used to measure the thickness of materials using a dial indicator-based comparison system.

Construction

It consists of:

A rigid frame (usually aluminum)

A movable upper spindle with a lifting lever

A spring-loaded mechanism for constant measuring force

Applications

Dial thickness gauges are used for measuring:

Leather

Paper and paperboard

Rubber

Plastic films

Glass

Sheet metal

Plywood and wooden panels

Accuracy and Measuring Faces

Typical accuracy: 0.01 mm

Flat measuring faces: used for soft materials (rubber, paper, films)

Spherical measuring faces: used for hard materials (sheet metal, glass, boards)

Graduations are usually in millimetres and microns.

Advantages

Quick and efficient inspection

Easy handling with grip and thumb trigger

Hard metal contact points for durability

Dial tolerance marks for easy interpretation

Additional Notes

Dial caliper gauges and dial thickness gauges are comparison gauges and should be used with:

Setting rings

Micrometers

Dial gauge stands are designed for comparison measurements using dial or digital indicators.

Dial indicators are widely used to:

Monitor tolerance variation during inspection

Measure deflection under load

Detect small dimensional changes in precision components

They are essential tools wherever small deviations must be detected and controlled accurately.

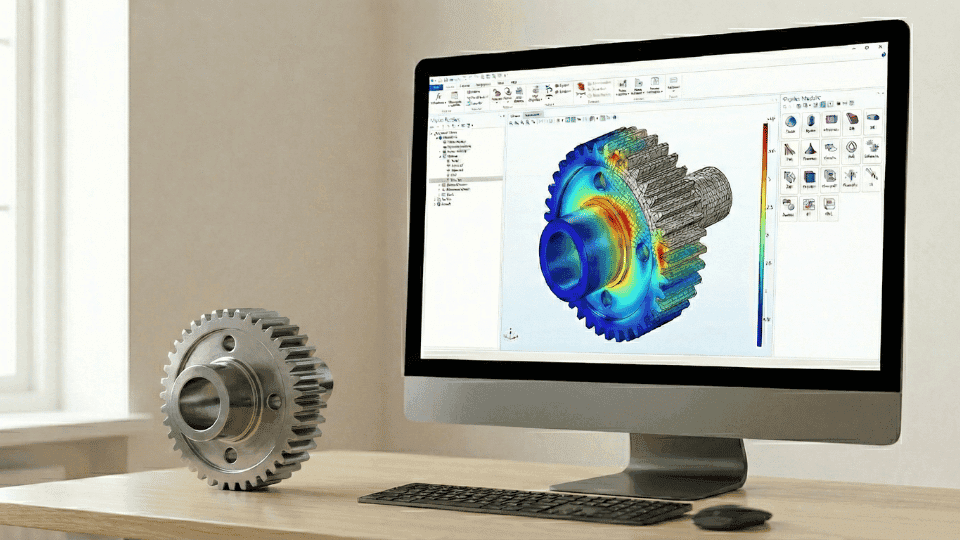

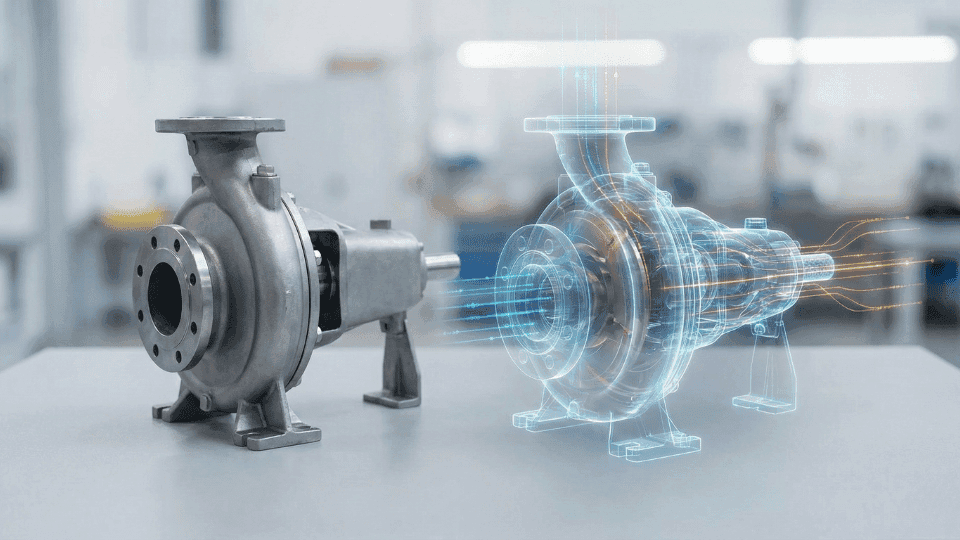

Our Courses

Complete Course Library

Access to 40+ courses covering various fields like Design, Simulation, Quality, Manufacturing, Robotics, and more.