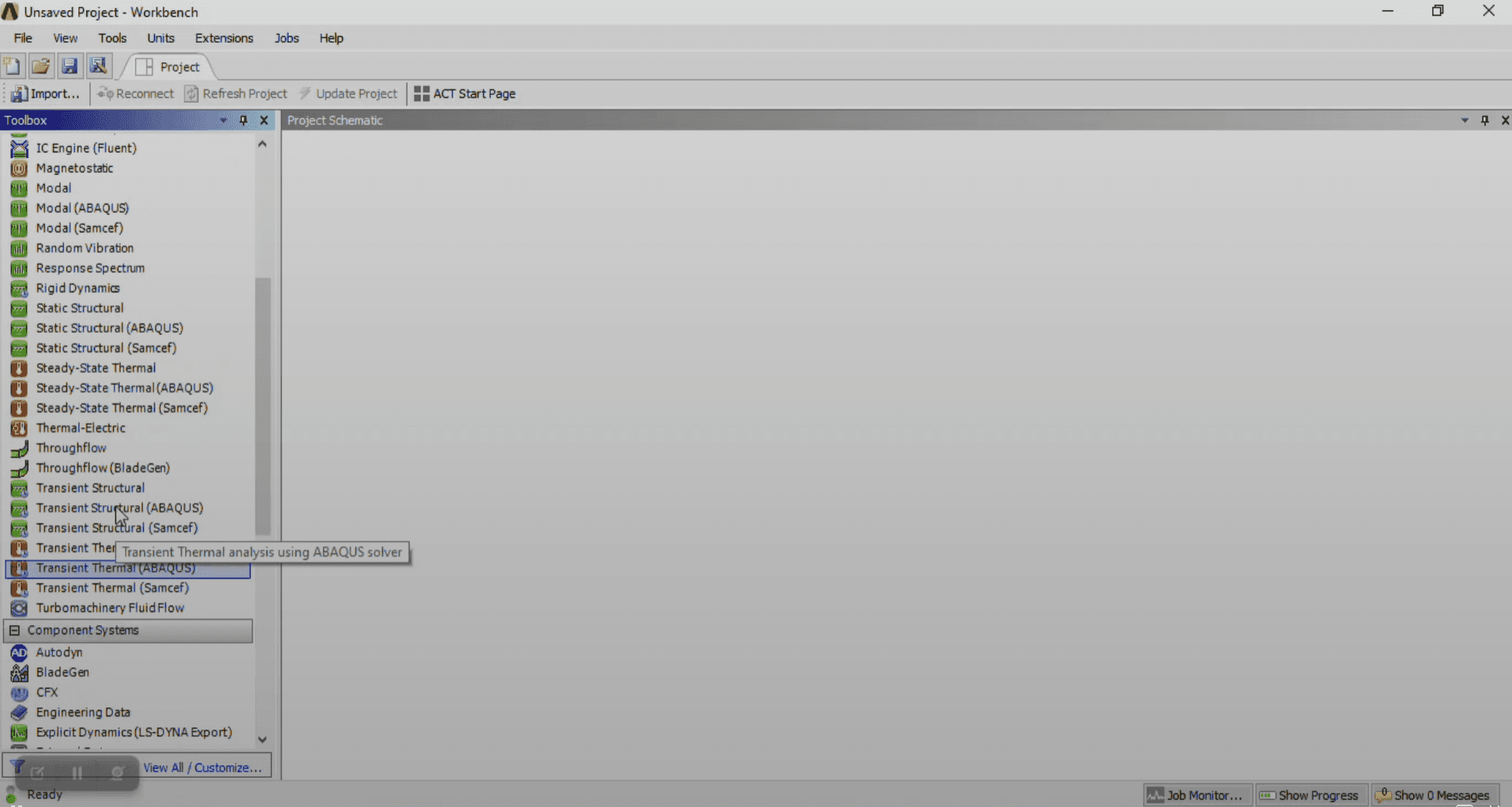

Abaqus vs Ansys for FEA: Key Differences And Use Cases

Jan 6, 2026

Deepak S Choudhary

🔧 Trusted by 23,000+ Happy Learners

Learn CAE & Simulation Tools

Learn the CAE tools engineers actually use: ANSYS, OpenFOAM, Abaqus, COMSOL & MATLAB -Start your journey here

Abaqus software and Ansys Software both deliver serious finite element results, but they fail in different places. This guide compares nonlinear behavior, workflow breakpoints, fracture options, and licensing reality. Use the quick tables plus an evidence pack to pick a tool you can defend in reviews.

Pick Abaqus for FEA when nonlinear contact or large strain owns the load path. Pick Ansys for FEA when you need broad multiphysics templates and scalable teams.

Validate either choice with contact sensitivity, material calibration, and stability checks. Sign off only after the evidence pack items are clean.

Most “Abaqus vs Ansys” comparisons argue features. Real projects break on setup discipline, contact governance, material data quality, and how your team proves credibility under review. So the goal here is not to crown a winner. The goal is to stop wrong answers that look right.

Implicit solves equilibrium per increment and is usually the choice for quasi-static nonlinear problems. Explicit advances dynamics with very small time steps and is often used for impacts, crushing, forming, and highly nonlinear contact.

One freshness note that matters for readers: Synopsys completed its acquisition of Ansys on July 17, 2025, and Synopsys said the combined portfolio is expected to deliver the first integrated capabilities in the first half of 2026. Day-to-day users still evaluate tools the same way: solver fit, workflow maturity, licensing fit, and validation expectations. (Synopsys News Releases)

Quick Pick

In practice, Abaqus software tends to win when the load path is governed by nonlinear contact, large deformation, and custom constitutive behavior. Ansys Software tends to win when you need broad multiphysics workflows, standardization, and easier onboarding across teams.

Decision Flow

Start

|

|-- Does contact + large strain dominate the load path?

| |-- Yes --> Bias toward Abaqus, then verify subroutine and contact controls

| |-- No --> Next

|

|-- Do you need multi-solver workflows and broad multiphysics in one ecosystem?

|-- Yes --> Bias toward Ansys, then verify HPC and license model

|-- No --> Pick based on team maturity and evidence requirements

Industry Use Cases Matrix

Industry | Typical Analysis | What Breaks First | Pick Bias |

Automotive | Crash, durability, joints | Contact stability, material curves | Abaqus for heavy nonlinear, Ansys for standardized durability workflows |

Aerospace | Composite structures, fasteners | Mesh quality, certification evidence | Bias to the tool your validation pipeline already trusts |

Industrial Machinery | Bolted joints, seals, and fatigue | Constraints and contact pairs | Abaqus when contact drives, Ansys when templates and reporting drives |

Energy | Pressure equipment, thermal stress | Material temperature data, creep choices | Ansys for coupled thermal structural, Abaqus for complex nonlinear |

Biomedical | Implants, soft tissue models | Material model calibration | Abaqus for advanced nonlinear materials, Ansys, when workflow governance is key |

Electronics | Thermal stress, package warpage | Coupling and boundary realism | Ansys for multiphysics breadth and integration |

One Reality Check Stat Block

If procurement asks, Are these vendors stable?” Use audited numbers, not vibes. Ansys reported total revenue of $2,544.809 million in its 2024 10-K.

Ansys also reported $528.014 million in 2024 R&D expense.

Dassault Systèmes reported €6.21 billion total revenue for FY2024.

What Actually Changes The Answer

From a solver standpoint, tool choice is rarely about a prettier stress plot. What matters first is what dominates the physics and where your workflow is most fragile.

Nonlinear Contact And Constraints

On real projects, contact definitions dominate stress results. Small changes in friction, penetration control, and constraint strategy can swing peak stresses and even flip the load path.

A defensible workflow includes a quick contact sensitivity check when contact drives the answer. If the decision metric swings, you do not have a solver problem. You have a modeling governance problem.

Material Calibration And Units Traps

The failure mode is usually input quality. Plasticity curves need a correct definition, valid strain ranges, and a correct temperature basis. Unit mistakes still happen in mixed CAD and simulation stacks, especially when supplier data and legacy material cards collide.

Treat material calibration like a controlled artifact. Store it, version it, and tie it to a test basis.

Implicit vs Explicit: The Practical Split

Implicit is usually the fastest route for stable quasi-static nonlinear work when increments converge. Explicit becomes the practical choice when events are dynamic, contact is violent, or convergence time is wasted.

Next, pick a solver based on what you can prove. A fast run that cannot be defended in review is still failed.

Modeling Comparison And Fracture Reality

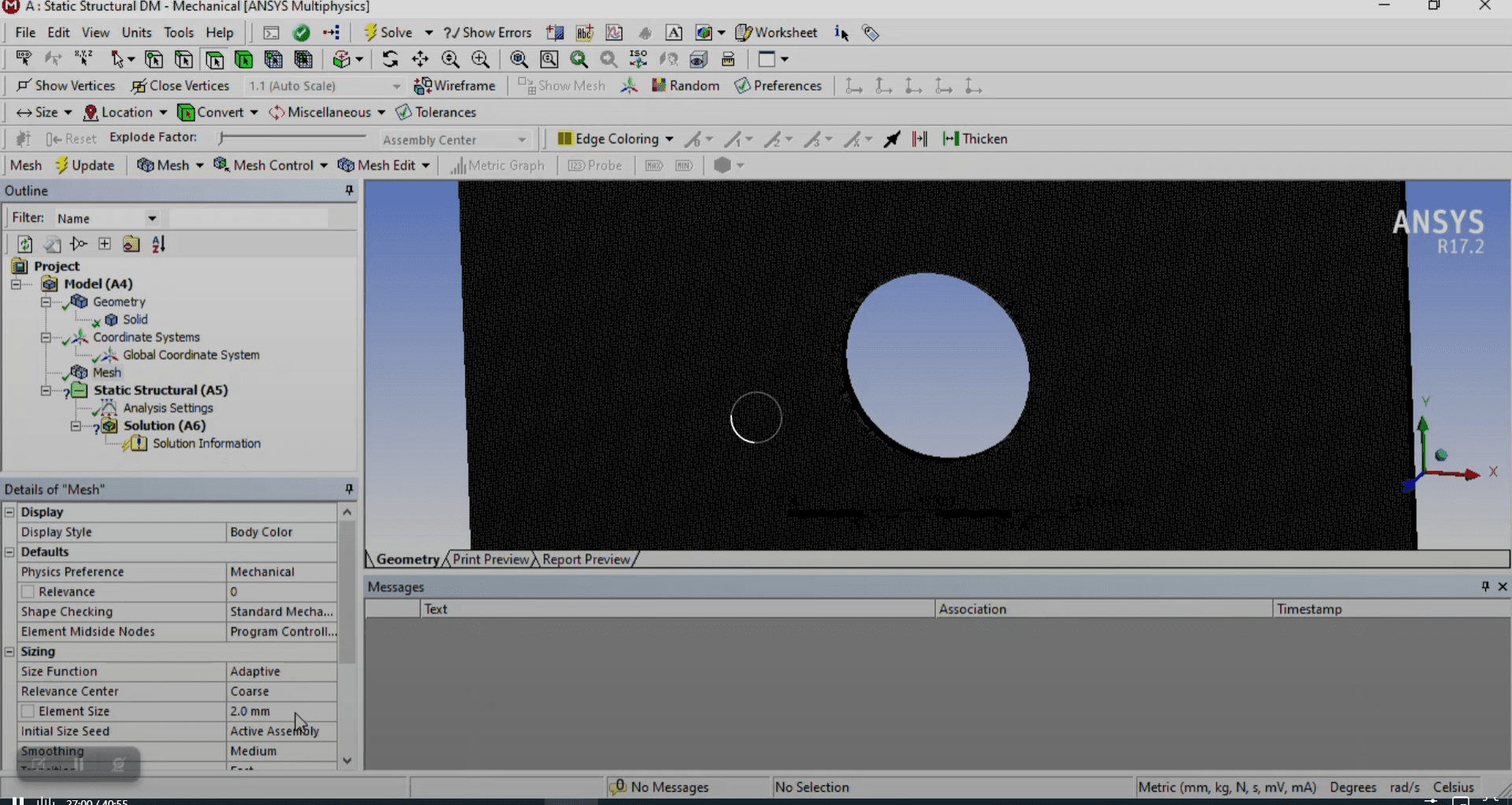

Plenty of comparisons talk about UI. Engineers care about where models break first and what to verify before the run becomes expensive.

Modeling Task | Common Mistake | What To Verify | Tool Choice Note |

Contact Pairs And Constraint Governance | Over-constraining and hiding it | Free body checks, reaction balance, contact status | Bias to the team’s most mature contact playbook |

Material Calibration Workflow | Using “generic” curves | Test basis, true vs engineering inputs, temperature | Bias to whichever pipeline stores calibration artifacts cleanly |

Large Deformation Meshing Strategy | Refining where gradients are fake | Mesh convergence on the decision metric, not plot beauty | Both can do it; discipline decides the outcome |

Explicit Event Setup And Sanity Checks | Bad mass scaling or time step assumptions | Energy balance, stable time increment trends | Bias to the tool your team debugs fastest |

Fixing The Fracture And Crack Modeling Story

Some SERP pages claim one side “wins” because the other “cannot help much.” That framing is usually wrong. Both ecosystems support XFEM-based fracture workflows, and the decision driver is rarely feature existence.

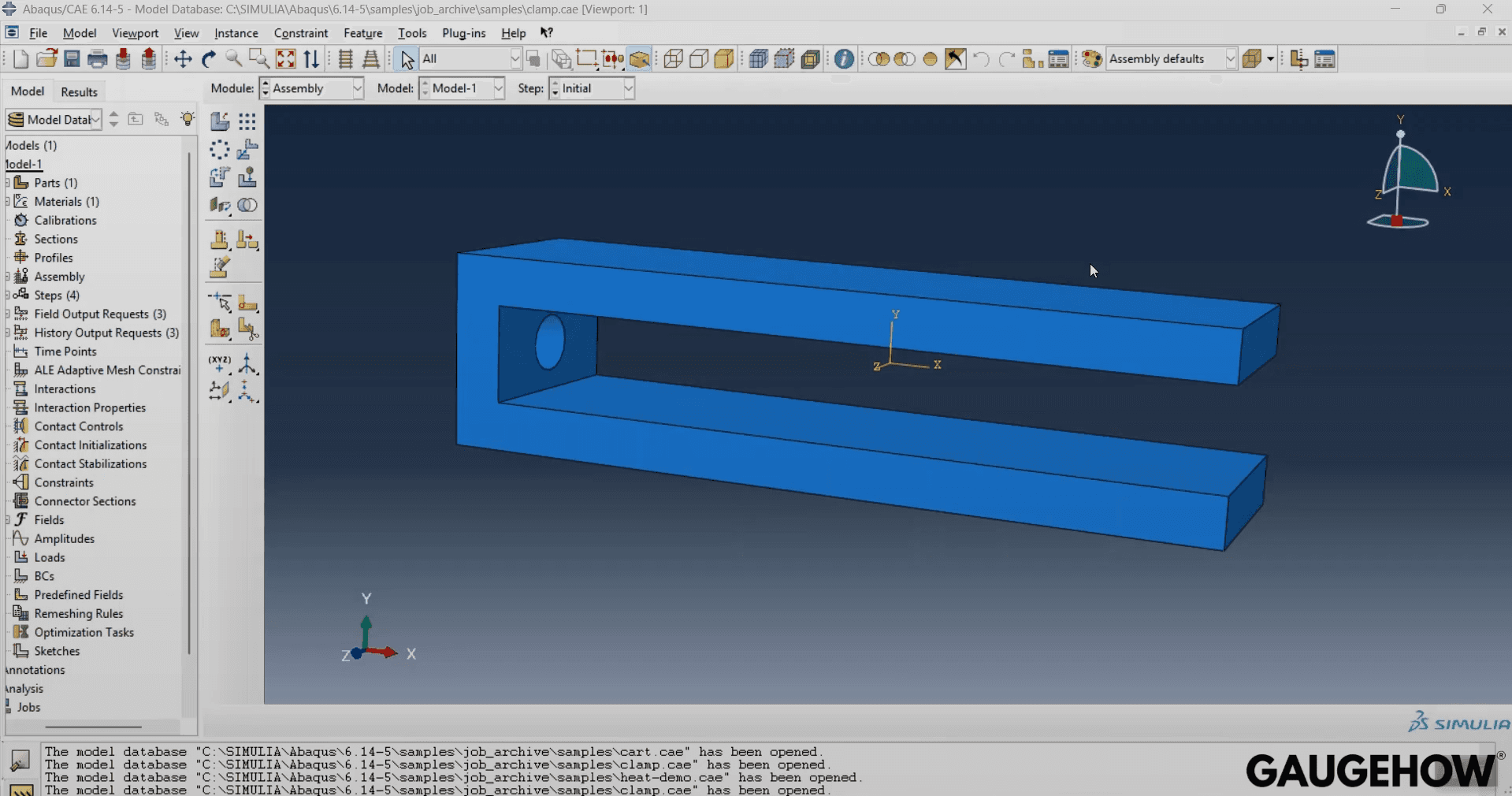

On the Abaqus side, Dassault Systèmes explicitly lists crack growth approaches,s including cohesive behavior, VCCT, and XFEM in its fracture and failure training summary material.

On the Ansys side, Ansys documentation for fracture analysis includes XFEM-based workflows for crack modeling and fracture analysis. (ansyshelp.ansys.com)

So what decides? Workflow maturity in your team, postprocessing expectations, and validation requirements. If your review process expects specific fracture outputs, pick the ecosystem where your template set, reporting, and correlation history are strongest.

Use fracture modeling sparingly. Crack growth simulations can be highly sensitive to mesh, enrichment regions, and material damage assumptions. The right pick is the one that you can validate against test data within your schedule.

Pricing, Licensing, And Procurement Reality

1. Pricing is quote-based.

2. Pricing depends on modules and usage scope.

3. It changes with seats and license style.

4. And also depends on solver throughput and HPC.

5. Pricing can shift with token or elastic consumption.

6. Pricing must be validated against your real run profile.

Indicative Abaqus Starting Points

GoEngineer publishes indicative starting points that are useful for early budgeting, while still requiring an official quote. Examples they list include a one-year lease “around $18,000,” and a permanent license “around $31,000” plus “roughly $7,500 yearly subscription,” with alternate structures for metered use. (goengineer.com)

Ansys Licensing Reality: Throughput Is The Cost Multiplier

Ansys does not publish a public price list. Purchasing begins with a sales or partner quote, then checks whether the license model holds up under your expected workload.

Most teams are surprised by HPC consumption. The licensing guides describe several HPC add-ons and the rules for stacking them across tool families. Under Elastic Licensing, HPC Packs are not supported, so requests for Packs are handled as Ansys HPC capacity instead.

Table - License Style

License Style | What Changes First | Who It Fits |

Named Seat | User access and onboarding speed | Small teams with stable usage |

Floating Network | Concurrency bottlenecks | Shared teams with staggered workloads |

Token or Credit Metering | Compute behavior and budgeting | Spiky workloads and burst compute planning (goengineer.com) |

Elastic Consumption | Usage tracking and governance | Large orgs needing centralized control (ansyshelp.ansys.com) |

Buyer Focused Table: Procurement Reality

Model | What To Ask Sales | What To Log For Cost Control |

Seat Model | Named vs floating terms, true concurrency | Peak concurrent users by week |

Token Model | Token to core mapping, cloud vs on prem rules | Tokens burned per run and runtime |

Elastic Model | What is billable, what is excluded | Elastic consumption by project, capability, and time slice |

HPC Add Ons | Pack rules, combination limits, elastic constraints | Cores per solve, parallel scaling, and queue delay |

Evidence Pack

This is the block most competitor pages skip. If risk is high, your evidence must rise with it. So treat sign off like a checklist of proof, not a feeling.

What I Must Show Before Sign-Off

The load path makes physical sense, andthe reactions balance.

Mesh convergence is shown on the decision metric.

Contact sensitivity is run when contact drives results.

Material inputs are traceable to the test basis and units.

Solver energy or equilibrium metrics stay controlled.

Evidence Pack Table

Evidence Item | What You Show | Why It Matters |

Decision Metric | Peak strain, deflection, or fatigue damage | Prevents “pretty plot” sign-off |

Convergence Proof | Metric stabilizes with refinement | Reduces mmesh-drivenerrors |

Sensitivity Proof | Contact or boundary perturbation | Exposes hidden load path flips |

Material Provenance | Curve source and range | Stops garbage in failures |

Correlation Plan | Test mapping and acceptance band | Aligns with validation expectations |

Decision Checklist

If you need a decision you can defend, start with physics dominance, then test workflow maturity, then confirm licensing fit. Put differently, pick the solver that reduces rework under review.

A good default is this: contact-heavy nonlinear tends to favor Abaqus for FEA, while multiphysics standardization tends to favor Ansys for FEA. Confirm the choice by running a small pilot model with the evidence pack, not by debating brand preference.

FAQs

1) Which is better for nonlinear contact problems?

Nonlinear contact is usually decided by setup discipline, not marketing. Bias toward the tool your team debugs fastest, and run a contact sensitivity check before trusting peaks.

2) Which is better for explicit dynamics like impact and crash?

Explicit is a workflow with strict sanity checks. Pick the ecosystem where your team already tracks energy balance, time step stability, and mass scaling rules consistently.

3) Can both handle fracture and crack growth with XFEM?

Yes, both have XFEM-based fracture workflows in their documentation. The practical choice depends on postprocessing needs and how you will validate against tests.

4) Why do teams underestimate cost?

Compute throughput is the usual budget surprise. Tie licensing discussions to cores per solve, parallel efficiency, and peak concurrency, especially when HPC options and constraints apply. (ansyshelp.ansys.com)

5) What is the fastest way to choose without regret?

Build one pilot model that matches your hardest failure mode, then run the evidence pack. The winner is the one who produces a stable decision metric with defensible proof.

References

Synopsys news release on completing the Ansys acquisition (July 17, 2025) and the first integrated capabilities timeline. (Synopsys News Releases)

GoEngineer guide with indicative Abaqus pricing starting points and licensing structures (tokens and credits). (goengineer.com)

Ansys Installation and Licensing documentation, Chapter 3 on HPC licensing and elastic constraints. (ansyshelp.ansys.com)

Ansys 2024 Form 10-K revenue and R&D figures.

Dassault Systèmes FY2024 results press release with the total revenue figure.

SIMULIA material describing fracture and failure approaches, including cohesive behavior, VCCT, and XFEM.

Ansys fracture analysis documentation describing XFEM-based fracture workflows. (ansyshelp.ansys.com)

Ansys's public licensing resources describing licensing solutions and concurrency framing. (Ansys)

Our Courses

Complete Course Library

Access to 40+ courses covering various fields like Design, Simulation, Quality, Manufacturing, Robotics, and more.