Here are 30 Measuring instruments for mechanical engineers. Every Mechanical Engineering student or employee should know about this.

Learn 30+ instruments in our online courses of Engineering Metrology and 3D Measurement

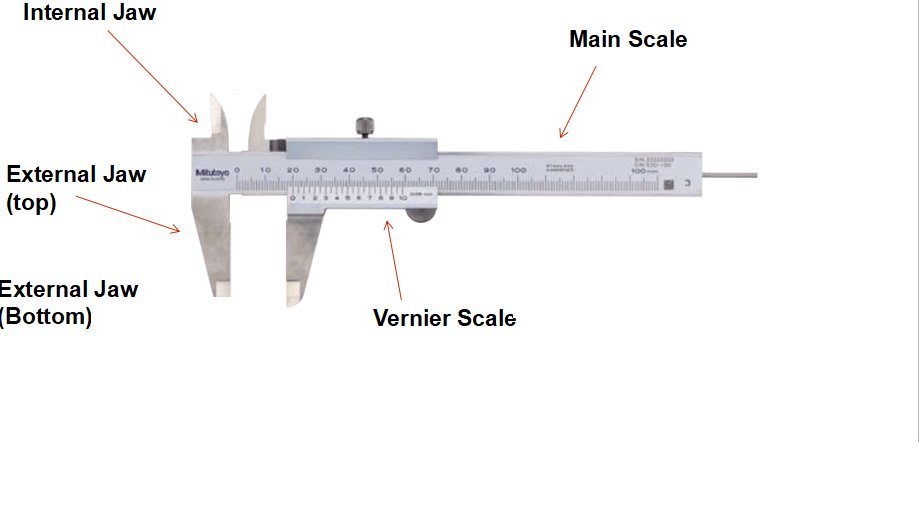

01. Vernier Caliper

Vernier Caliper is a widely used linear measurement instrument with a least count of 0.02 mm. It is used to measure linear dimensions like length, diameter, depth.

It is a Basic Instrument of measurement, consisting of two types of scale

The main scale and the Vernier scale can slide along the main scale. Two types of measurement we can do, the first one is through the external jaw (measure external dimensions) and another one is the internal jaw (measure internal dimensions).

02. Outside Micrometer

External Micrometer is also known as Outside Micrometer or External Micrometer.

It is used to check the outside diameter of the circle by the means of the accuracy of 0.01 mm or up to 0.001 mm.

Vernier type Micrometer gives highest acceptable accuracy of 1 micron such gauge is vernier type micrometre.

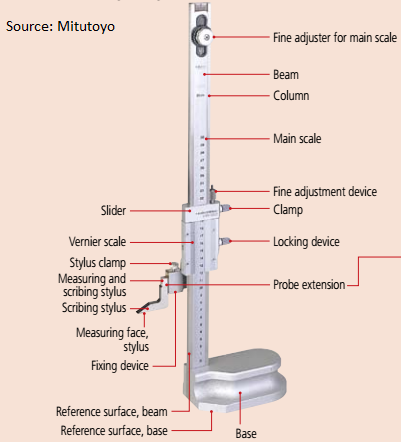

03. Vernier Height Gauge

Vernier height gauge used to measure vertical dimension from reference ground. Vernier Height Gauge consists of a graduated scale or bar that is held in a vertical position by a finely ground fixed base.

The graduated scale has the least count of 0.02 mm as Vernier Caliper has. And the way of taking a reading of measurement in Vernier Height Gauge is the same as in Vernier gauge.

learn more about Vernier height gauge in our Advance Engineering Metrology Course.

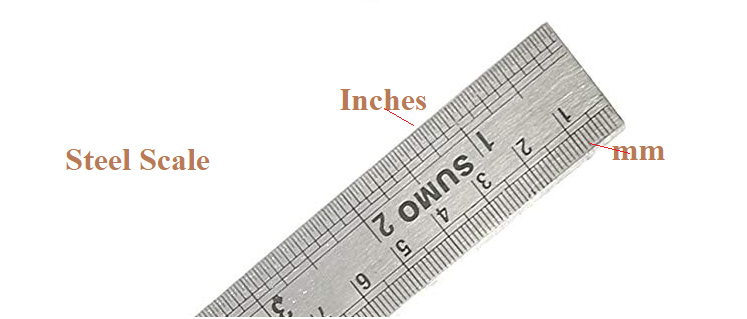

04. Steel Scale

Steel scale is a single piece linear measuring instrument.

The steel scale indicates two units that are cm and inches, cm division on one side and inches, on another side.

05. Vernier Depth Gauge

Vernier Depth Gauge as the name suggests is used to measure the depth from the surface of reference of an object.

Vernier calliper also has a depth bar but this can not be used as the standard measurement.

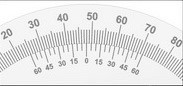

06. Vernier Bevel Protractor

A simple protractor is a basic device used for measuring angles with a least count of 1° or ½°. Bevel Protractor is an angular measuring instrument capable of measuring angles with a least count of 5’.

The protractor dial is graduated in degrees with every tenth degree numbered. The sliding blade is fitted into this dial I.e. it may be extended to either direction and set at an angle to the base.

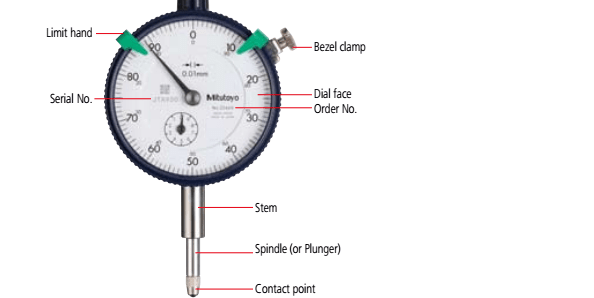

07. Plunger Dial Gauge

The dial indicator or the Plunger dial gauge is one of the simplest and the most widely used mechanical comparators.

First of all the use of plunger dial gauge used to compare work-pieces against a master

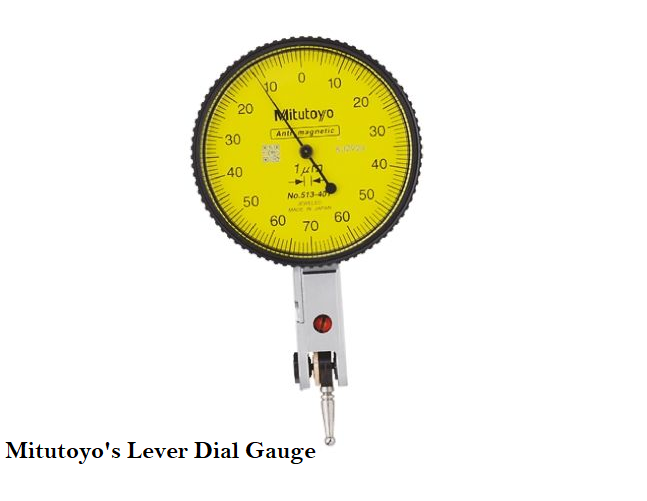

08. Lever Dial Gauge

Lever Dial Gauge is also known as Test Indicator. It is used to measure sensitive contact.

Lever Dial gauge usually measure up to 0.80 mm. But some special type lever dial design for measurement up to 2 mm.

learn more about dial gauge in our Advance Engineering Metrology Course.

09. Engineering Square

A ruler can be used to draw straight lines but there is no guarantee that the line drawn is accurate and exactly straight, this is where the engineering square is brought into use.

An engineering square also known as a machinist square is similar in size and construction to a try square.

It is a tool used for making straight lines and is used to measure angles.

10. V Block

In Industries where precise marking and firm holding of objects is required, V-Blocks play a major role and are extremely important metalworking jigs.

The construction had two clamps: a screw clamp and a U shaped handles like a clamp and a V-block.

11. Radius Gauge

Gauges are derived from the French word”jauge” which means the result of the measurement. We are all aware that gauges are used to measure the thickness, size or capacity of something.

Likewise, radius gauges are instruments that are used to measure the radius of the object.

The radius gauge is combined with another gauge known as fillet gauge which in mechanics means a rounding of the part design.

12. Digital Vernier Caliper

Digital Vernier Caliper is upgrading the version of Analog Vernier Caliper, which is a widely used linear measurement instrument with a least count of 0.01 mm, more accurate than Analog.

This Digital type of vernier is similar to Analog Vernier Caliper Instead Dimension output in Digital Manner is more convinces than the analogue type.

It also consists of two types of scale –

The main scale and the Digital display can slide along the main scale. Two types of measurements we can do, the first one is through the external jaw (that measures external dimensions like shaft) and another one is the internal jaw (measure internal dimensions like a hole).

learn more about digital Vernier Caliper in our Advance Engineering Metrology Course.

13. Digital Micrometer

Digital Micrometer is a very popular instrument these days because of its ease of compactness of taking an observation.

Digital Micrometer can observe measurement in mm or inch depending upon our need basis.

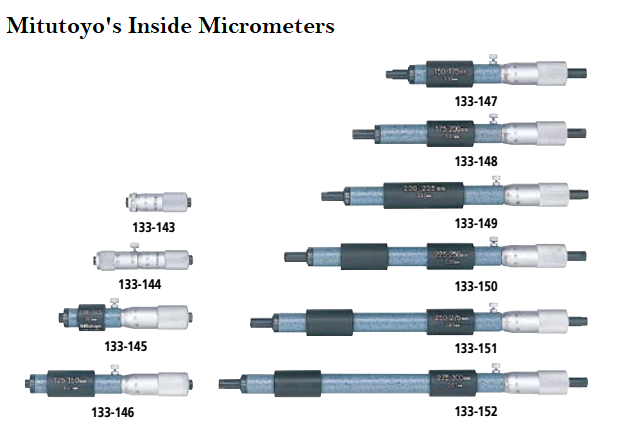

14. Inside Micrometer

Inside Micrometer is used to measure the larger internal dimension. Inside Micrometer can measure the internal Diameter of holes and registers.

Types of Micrometer

There are various types of micrometres available in the industry each used for a specific purpose. One such micrometre is the “Inside Micrometer”.

The inside micrometre is used to measure the inner diameter of objects that are bounded by walls, cylindrical bore or hollow pipe. There are two types of Inside Micrometer

- Analog type Inside Micrometer

- Digital type Inside Micrometer

15. Depth Micrometer

We also measure depth through the Vernier calliper, but the Vernier calliper does not deliver as much accuracy and precision, because the extension rod of the Vernier calliper has no standard, it is used only for comparison purposes.

A depth micrometre is used to measure the depth of an object with precision and accuracy with least count of 0.01 mm. The measuring span is 25 mm just like in micrometre, which can change by changing upsetting rod.

learn more about all micrometres in our Advance Engineering Metrology Course.

16. Measuring Tape

Measuring tape is used to measure long distances.

17. Digital Height Gauge

The electronic Height gauge is a very compact, simple, easy to use instrument widely used in industries, tool rooms, workshops etc.

Some think you should consider while handling Electronic Height Gauge, Because of the cost of Electronic Height gauge matter in any industries or organization.

18. Electronic Height Gauge

An electronic height gauge is an advanced form of the height gauge. It has higher accuracy and multifunction.

An Electronic height gauge can measure diameter, angle, parallelism, squareness along the length.

19. Digital Universal Caliper

Digital universal calliper is widely used to measure the inner and outer length of work-piece

20. Sine Bar

Sine bar is a precision angle measuring instrument along with slip gauges. The name suggests that the Sine bar work on the sine principle. Slip gauge is used to build up the height of the sine bar.

The required angle is obtained when the difference in height between the two rollers is equal to the sine of the angle multiplied by the distance between the centres of the rollers.

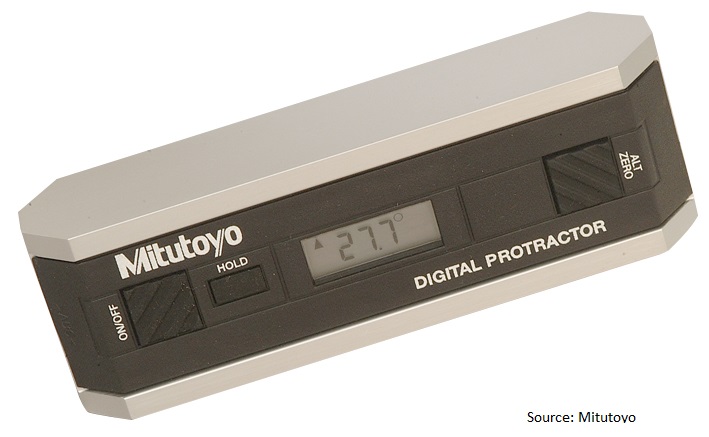

21. Digital Protractor

Digital Protractors measure an angle over 360 degrees with high accuracy of 0.1 degrees. Digital Protractor is very simple and easy to measure the angle by just putting it between levels or surfaces.

22. Spirit level

To check the level of any surface or table, a spirit level is used for levelling.

23. Slip Gauge Set

Slip Gauge is a set standard size rectangular shape block. Slip gauges are available in standard sets in both metric and inch units.

In metric units, sets of 31, 48, 56, and 103 pieces are available.

For example, the set of 103 pieces consists of the following:

- One piece of 1.005 mm

- 49 pieces ranging from 1.01 to 1.49 mm in steps of 0.01 mm

- 49 pieces ranging from 0.5 to 24.5 mm in steps of 0.5 mm

- Four pieces ranging from 25 to 100 mm in steps of 25 mm

24. Bore Dial Gauge

Bore Dial Gauge is used to measure the inner diameter of the hole, it is a gauge fitted with a plunger dial gauge. In this video, you are able to know how to measure diameter with a bore dial gauge.

Bore dial gauge used within the standard range that means bore dial gauge have a standard set of pins(anvils) with the variable range of up to 2 mm.

25. Feeler Gauge

A Feeler gauge is used to measure the clearance between two parallel flat faces for example piston and cylinder. As the name suggests, the feeler gauge is called to measure neither tide nor freely.

Feeler gauges are used for the measurement of clearances.

It is a tool that measures air or narrow gap widths between two surfaces in engines and machinery.

Feeler gauge available in no. of the blade-like 10,13,20 and 28. With a step of 0.05 and 0.10 mm.

26. Thermocouple

Thermocouples consist of two dissimilar conductor wires, made from different metals. These wires are welded together at one end, forming a junction used to measure temperature.

27. Thermister

Thermistors have a high coefficient of resistivity. Thermistors are made of semiconductors of solid type.

The suitable temperature measuring range for thermistors is -100 degrees Celsius to 300 degrees Celsius. Some special type thermistors can measure up to 600 degrees of temperature.

The change in temperature is measured by changes in its resistance. So, the Wheatstone bridge circuit is used for it.

Also, a thermistor can convert changes in temperature to corresponding changes in voltage as a current.

28. Barometer

Air gets pulled down by gravity and hence air exerts pressure on objects. One such example of measurement is known as a barometer.

Barometers are scientific instruments that are used for the measurement of atmospheric or air pressure. It is an important and essential tool used in the meteorological department for forecasting short term weather and altitude changes.

The barometers should be kept at the same level and cannot measure air pressure above the altitude of 5,000 feet. Initially, water-based barometers were used, later it was replaced by mercury and aneroid barometers which the two most commonly used barometers.

29. Snap gauge

Snap gauge is GO and NOGO type gauge. That means snap gauges consist of 2 fixed measured distances or gaps, one is known as GO and another one is known as NOGO.

30. Plain Plug gauge

Plug gauge is used for the assessment of the hole or diameter of an object. With specified tolerance of GO and NOGO side, plug gauge is also known as pin gauge.

Behalf of checking the diameter plug gauge also use in comparing, setting, calibrating of other gauges.

31.Galvanometer

In an electric circuit, even if the switch or loop is closed, it is difficult to know whether the current is flowing, hence for this purpose galvanometer was introduced in the circuit.

Great, thanks for

Thanks for writing in Deepanshu

Thank you so much ☺️

Thanks chethan

measurements standard may differ for various conditions. are you agree

Hi,

Thanks for writing!

Yes, of course. its depends upon environmental conditions, coefficient of thermal expansion of material, master used, operator skills etc.

Thank you 😊

Always Welcome

thank you for providing useful information about mechanical measuring instruments

thanks for writing 🙂

Thsnk for this useful information

Thanks 🙂

This is very helpful, thank you very much

Welcome 🙂

That was a really a very useful information on measuring instruments.

All the tools mentioned above plays an important role in measurement process.

thanks to helping our interviews,,,,

thanks 🙂

[…] 30 Measuring Instruments […]

Thank you for shareing yours experices sir thank you lot is very important of mechnical enhineering dept from india karnatka mysore

[…] 30+ Measuring Instruments for Mechanical Engineer […]

[…] aboard the USG Ishimura with genre-defining strategic gameplay. Repurpose and improve Isaac’s engineering instruments to creatively defeat enemies with […]

[…] 30+ Measuring Instruments for Mechanical Engineer […]

This post on “30+ Measuring Instruments for Mechanical Engineers” is a veritable wealth of knowledge! As a mechanical engineer, I’m always looking for equipment and devices that will allow me to correctly measure and evaluate various parts of my projects.

[…] a vernier caliper, micrometer, and other measuring instruments is not feasible for inspecting the parts produced in mass production, because of the skill involved […]