Real-world applications of CFD: Simulation & Analysis 2026

Dec 27, 2025

Deepak S Choudhary

🔧 Trusted by 23,000+ Happy Learners

Learn CAE & Simulation Tools

Learn the CAE tools engineers actually use: ANSYS, OpenFOAM, Abaqus, COMSOL & MATLAB -Start your journey here

Real-world applications of CFD guide real engineering decisions today. You predict flow behavior and defend one measurable KPI. You show evidence checks, sensitivity results, and clear assumptions. You package outputs in a repeatable review format. That is how you reduce prototypes and also reduce risk.

Computational Fluid Dynamics: What It Is And Why Teams Pay For It

You use Computational Fluid Dynamics when testing is slow. You also use it when testing is expensive. It predicts liquid and gas flow using conservation laws. So the method stays grounded in physics for reviews. (Ansys)

In real programs, you mix simulation with targeted tests. Honda announced a $124 million aeroacoustic wind tunnel. To be honest, that shows testing is valuable, but costly. (Honda News)

When you write the plan, state the decision clearly. Then state the KPI you will defend in the review. This keeps the scope stable when deadlines rise and pressure builds.

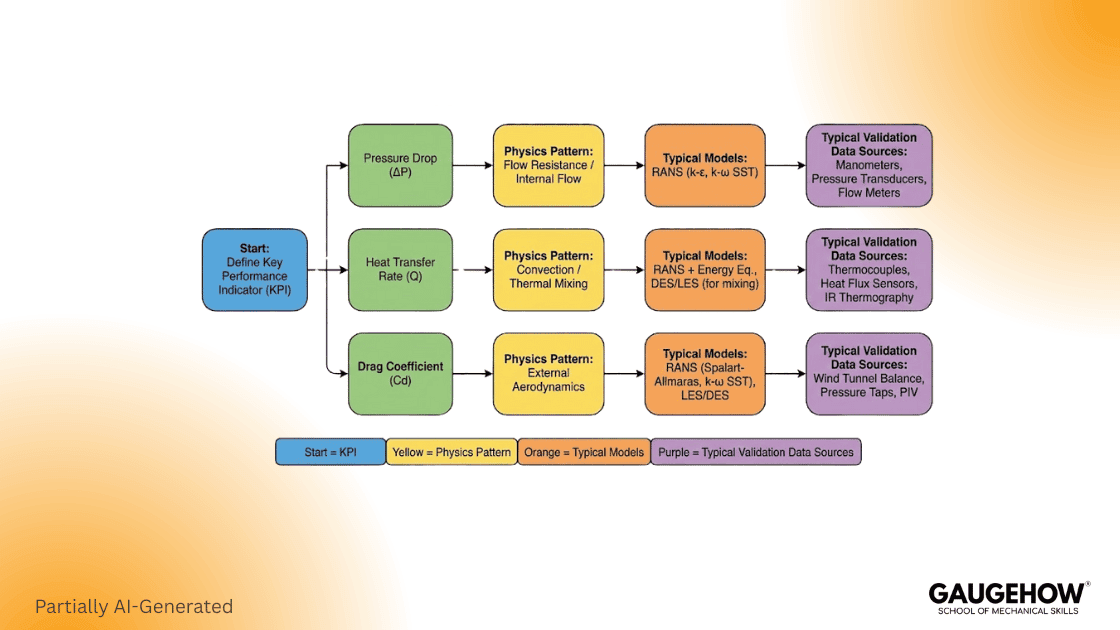

Pick Your Physics Pattern

Most engineering work fits a small set of patterns. If you name the pattern early, your setup becomes simpler. Your review story also becomes much easier for others.

External Flow Pattern

This pattern covers vehicles, drones, and buildings. You track forces, separation, and wake behavior consistently. The decision KPI is often aerodynamic drag for efficient work.

Internal Flow Pattern

This pattern covers ducts, manifolds, and valves. You track loss, flow split, and uniformity across variants. The decision KPI is often pa ressure drop for system sizing.

Thermal Pattern

This pattern covers electronics, batteries, and HVAC equipment. You solve momentum and energy together, so heat transfer drives the outcome. In practice, thermal management is the constraint you cannot ignore.

Reacting Pattern

This pattern covers burners and reactors. The scope is tight here because combustion modeling can be sensitive. You document assumptions early, so reviews stay calm.

Multiphase And Particles Pattern

This pattern covers sprays, bubbles, and dust transport. The regime matters because multiphase flow closures can dominate outcomes. You treat inputs as risks, not as defaults.

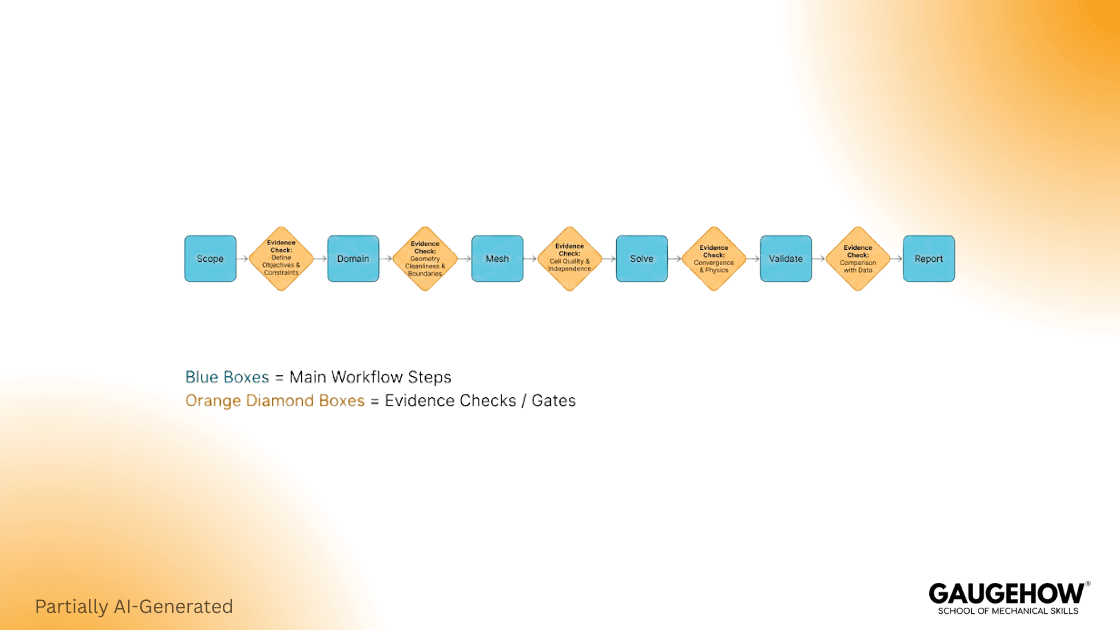

CFD Simulation Workflow You Can Repeat

A CFD simulation is a chain of choices, not a button. You control that chain by locking the scope and evidence gates. This is how you prevent rework late in the week.

Scope The Decision, Not The Picture

Write one sentence that states the decision clearly. Choose one primary KPI and two checks now. This keeps plots from running the project today.

Domain And Inputs That Prevent Fake Physics

Build the domain so that flow can develop naturally. Simplify geometry carefully, and log every change you make. Lock the boundary conditions early, because late changes destroy comparisons.

Mesh Strategy With A Planned Sensitivity Check

Resolve gradients near walls and shear layers first. Then run three meshes and track the same KPIs. This is where mesh independence becomes a credibility lever.

Model Choices That Match The Pattern

Pick models based on expected physics and data. State the turbulence model choice plainly, and keep it consistent. Consistency is what makes the result defensible in reviews.

Convergence That Matches The KPI

Residuals matter, but monitors matter more in review. Track mass balance, energy balance when needed, and the KPI. Treat oscillation as a sign that you must change strategy.

CFD Analysis Evidence Ladder For Reviews

A CFD analysis must survive hard questions in review. NASA’s tutorial explains verification and validation clearly, so use it as your baseline framing for what to check and when. (grc.nasa.gov)

Run validation like a plan, not a hand wave later. Gate one: close mass and energy and pass sanity bounds. Gate two: vary mesh, timestep, and domain until the KPI stops moving. Gate three: compare with data where it exists, then write uncertainty bands.

Boeing’s V and V guidance makes one point: document what you ran, why you ran it, and what you assumed.

What Breaks Trust Fast

Unclear inputs create unclear answers, even with clean solves. Changing setups between variants breaks fair comparison. A tight change log keeps your story consistent.

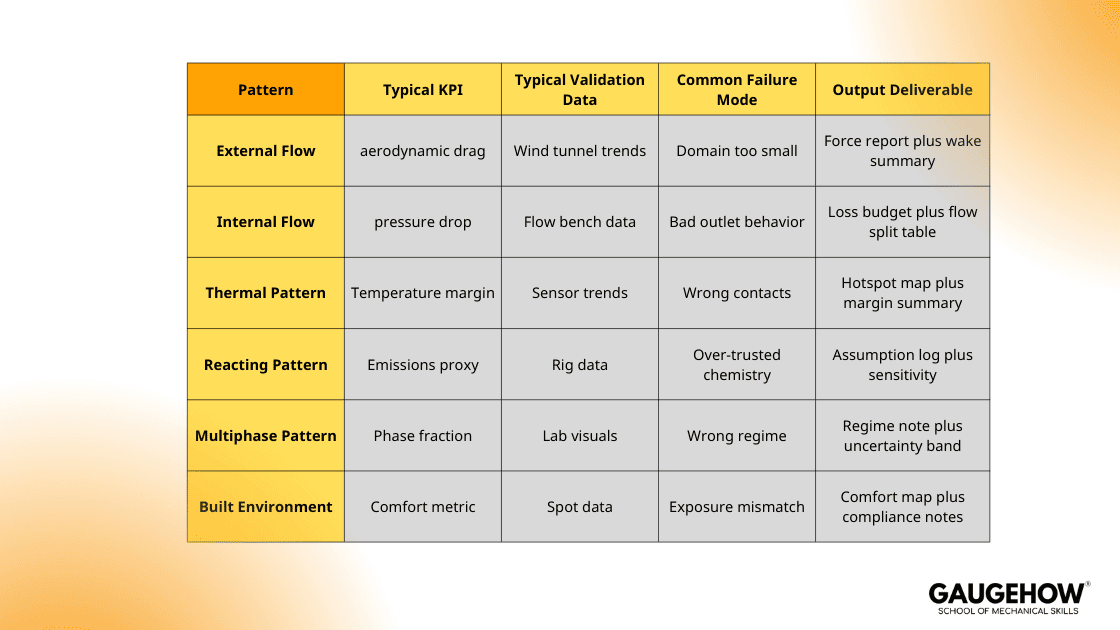

Pick Your Industry

Competitor pages list industries, but they skip structure. Here, you map each industry to a physics pattern. Then you map KPIs to deliverables for decisions.

Aerospace And Drones

Early external flow work is about trends, not perfect absolutes. Track forces and separation across the operating envelope. Tie outputs to requirements and compare with any available data.

Automotive And EV

External flow supports range and stability decisions. Internal flow supports cooling and cabin systems decisions. In EV work, thermal management often limits allowable performance.

HVAC And Buildings

Treat built environment CFD like a test you must defend, not a picture you can sell. Domain sizing and grid choices shift the loads, so set a blockage ratio target and record it per run.

Prioritize mesh quality and model assumptions because both drive error. Use a short checklist before trusting visuals.

Electronics Cooling

Electronics work is thermal pattern work with tight margins. Your report should show hotspot maps and margins. Explain where heat transfer is dominated by convection versus conduction.

Energy, Turbomachinery, And Reacting Systems

Turbomachinery work is about loss and stability margins. When reacting, physics is involved, scope claimsare tightly. Document combustion modeling assumptions, inputs, and sensitivity clearly.

Process And Chemical Systems

Mixing and reactors often involve droplets or solids. If so, multiphase flow assumptions must be written clearly. Choose measurable KPIs, then plan correlations and uncertainty bands.

Pattern To Deliverable Table

This is the table that blocks weak reporting. It forces KPIs, validation sources, failure modes, and outputs. It also makes scanning productive, rather than shallow.

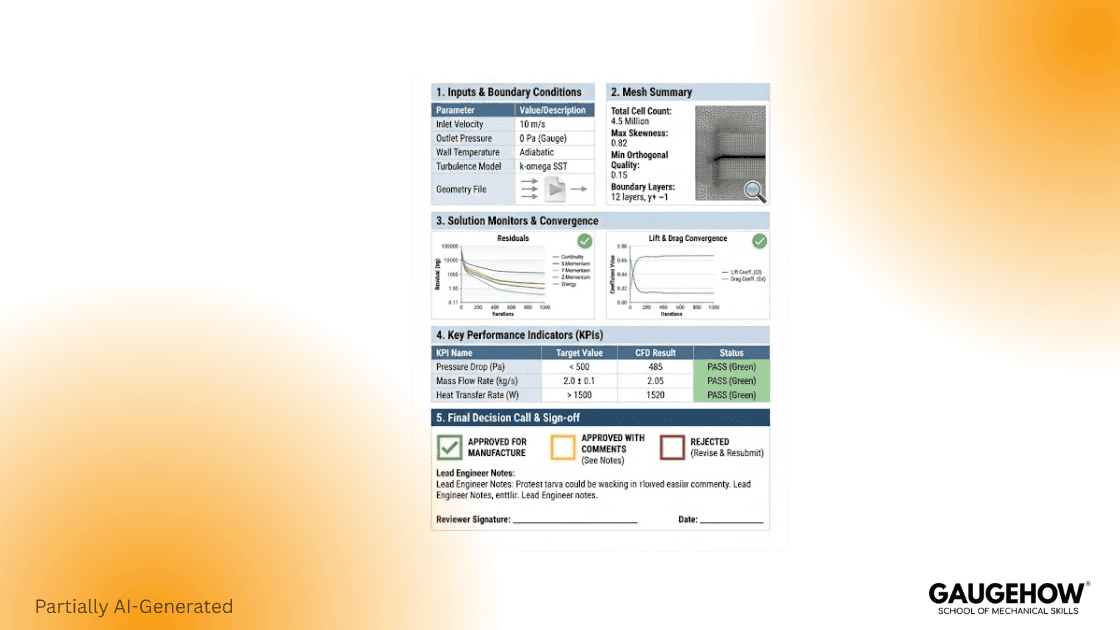

Design Review Pack Template

Most pages teach concepts, but they skip packaging. Packaging is where time is lost in real teams. This one-page template makes reviews repeatable and calm. Use this file as a Hub.

Design Review Pack Checklist:

Decision statement, KPI, and acceptance threshold

Geometry simplification log and version notes

Inputs table with rationale and data source

Mesh summary with refinement plan and results

turbulence model choice with near-wall approach

Monitor plots tied to the KPI and mass balance

Sensitivity summary and the action you took

Final KPI table and decision recommendation

Tools, Scaling, Licensing, And Cost

Keep this page focused on evidence, not shopping. Still, ask hard questions before you scale runs. Ask how licensing behaves under high concurrency today. Ask how you store results with traceability safely.

Limitations And When Simulation Is The Wrong Tool

If inputs are unknown, uncertainty can dominate outcomes. If the physics is strongly transient, averages can hide mechanisms. If coupling is strong, simplified models can mislead. So use tests instead or tighten the scope early.

FAQ

How Long Does A Typical Run Take

Small, steady cases can finish within hours. Large transient cases can take days on clusters. Mesh size, model choice, and convergence targets drive the timeline.

What Accuracy Should You Expect

Accuracy depends on inputs and validation options. So, publish sensitivity results and uncertainty ranges always. Reviewers trust ranges more than certainty in practice.

When Should You Prefer Testing

Use testing when compliance requires physical evidence. Use it when inputs cannot be trusted fully. The best programs use both, and they use each efficiently.

Conclusion

You do not win with extra plots and extra claims. You win with a clean plan, clear evidence, and clean reporting. Computational Fluid Dynamics works best with a stable scope. You lock inputs, run sensitivity checks, and report consistently.

If you follow that system, your CFD simulation becomes dependable. Your CFD analysis becomes defensible in review, too. And the page earns links because your Proof Pack is usable.

Also Read:- Best CFD Software 2026: Commercial Vs Open Source Guide

Our Courses

Complete Course Library

Access to 40+ courses covering various fields like Design, Simulation, Quality, Manufacturing, Robotics, and more.