Quality Control Interview Questions

Jan 18, 2026

Deepak S Choudhary

🔧 Trusted by 23,000+ Happy Learners

Industry-Ready Skills for Mechanical Engineers

Upskill with 40+ courses in Design/CAD, Simulation, FEA/CFD, Manufacturing, Robotics & Industry 4.0.

Metrology is controlled measurement used to confirm a part meets drawing requirements with confidence. This Q&A covers least count, accuracy vs precision, vernier caliper and micrometer readings, gauge blocks, CMM basics, calibration and traceability, repeatability, common measurement errors, GR&R, and core ISO 9001 and ISO/IEC 17025 expectations that protect inspection decisions.

In quality control, metrology is what makes a dimension believable. It is the practical system of instruments, method, environment, and records that turns a tolerance into a defensible pass or fail.

Ever measured the same feature twice and got two different numbers, then wondered if the part drifted or your measurement method did?

This guide answers the exact queries engineers search for, and interviewers ask, from least count and zero error to gauge blocks, CMM setup, ccalibrationon and uncertainty, plus measurement system checks like GR&R, with short answers that stay decision-focused.

Pick The Right Instrument For The Tolerance

Tolerance Band (Typical) | Best-Fit Instrument | What Usually Goes Wrong | Quick Operator Habit |

±0.10 mm | Vernier caliper/steel rule for rough checks | Jaw tilt and parallax style misread | Seat square, read at eye-normal |

±0.02 mm | Micrometer/comparator with master | Force distortion and backlash | Use a ratchet, approach one direction |

±0.005 mm | Comparator + master / CMM for geometry | Thermal drift, poor datum alignment | Let the part soak near 20 °C, lock the datums |

Metrology Fundamentals

Q1. What is metrology in quality control?

Metrology in QC is measurement done with a controlled method, so the result can be trusted for acceptance decisions. The focus is reliability, not just getting a number on the screen.

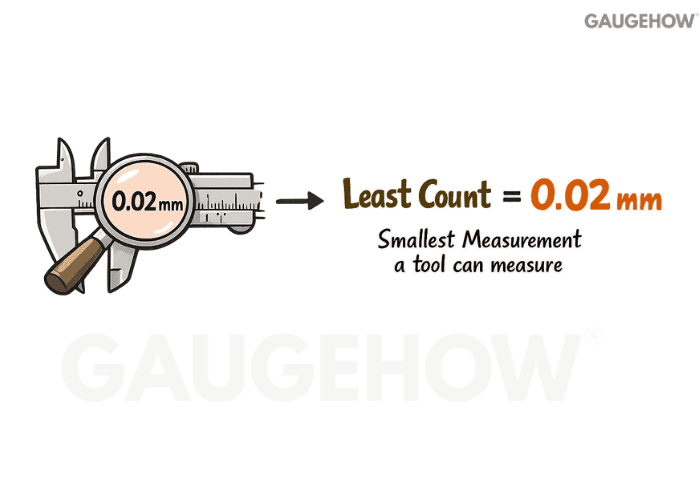

Q2. What is the least count?

Least count is the smallest step an instrument can resolve meaningfully.

If the least count is large compared to the tolerance, inspection turns into rounding, and rounding turns into wrong decisions.

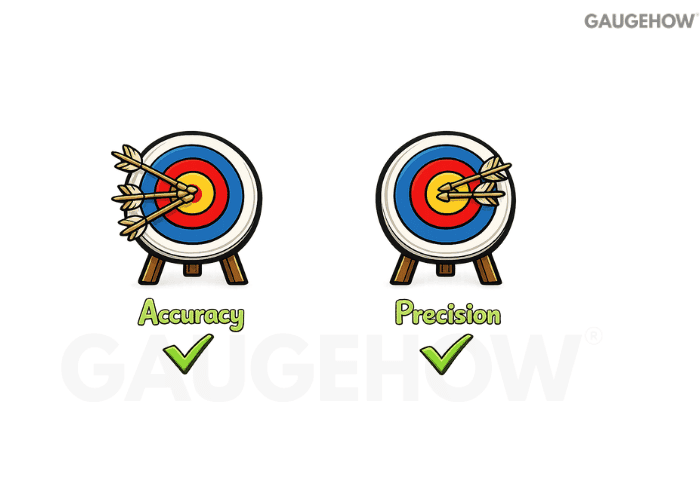

Q3. What is the difference between accuracy and precision?

Accuracy means closeness to the true value. Precision means the readings cluster tightly.

A tool can be consistent and still wrong if it has an offset or a poor reference.

Q4. What is resolution in measurement?

Resolution is what the display can show. It is not a promise of accuracy. A caliper showing 0.01 mm does not guarantee your measurement is accurate to 0.01 mm.

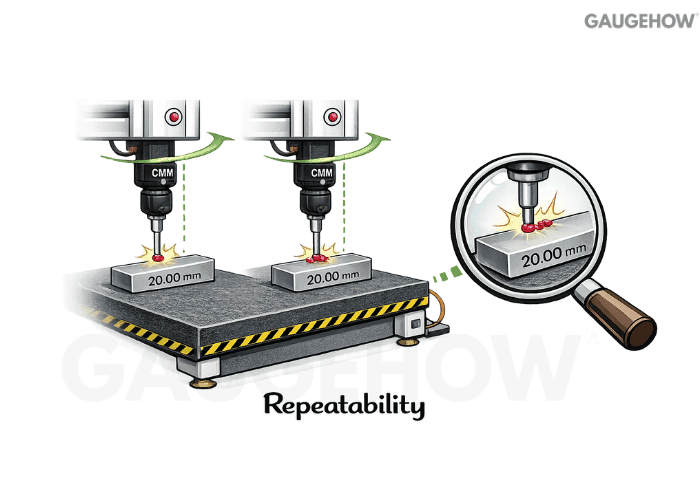

Q5. What are repeatability and reproducibility in measurement?

Repeatability is the same operator, same tool, same setup variation.

Reproducibility is variation when the operator or setup changes. Together, they tell you whether the measurement system is stable enough to control a process.

Q6. What is traceability in calibration?

Traceability means your measurement links back to standards through a documented calibration chain with stated uncertainty. If you cannot show that chain, your number is not audit-proof.

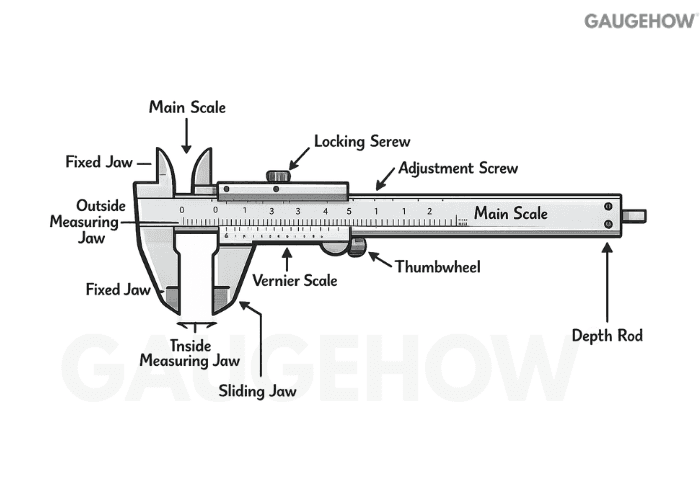

Vernier Caliper And Height Gauge

Q7. How to calculate the least count of a vernier caliper?

Least count is the difference between one main scale division and one vernier scale division.

For common metric verniers, it is often one main scale division divided by the number of vernier divisions.

Q8. How to read a vernier caliper step by step?

Read the main scale just before the vernier zero, then add vernier coincidence count times least count, then apply zero correction.

Example: A shoulder measures with the main scale at 24.00 mm, the 13th vernier line matches, the least count is 0.02 mm, so 24.00 + (13 × 0.02) = 24.26 mm, then correct for zero error if present.

Q9. What is zero error in a vernier caliper?

Zero error exists when the jaws fully close, but the vernier does not read zero. If the instrument shows +0.03 mm at close, subtract 0.03 mm from all readings. If it shows −0.03 mm, add 0.03 mm.

Q10.Whatis the parallax error in a vernier caliper?

Parallax happens when your viewing angle is off, so the coincidence line looks shifted. Keep your eye normal to the scale and avoid reading under glare, especially on worn scales.

Q11. How to measure the internal diameter with a vernier caliper?

Use the inside jaws, keep the tool square to the bore axis, and gently rock to find the maximum reading. That maximum is usually the true diameter, while tilted positions under-read due to cosine-style misalignment.

Q12. How to measure depth using a vernier caliper?

Seat the base flat on the reference surface and extend the depth rod until it touches the bottom lightly. Any base tilt creates cosine error, so stability of seating matters more than speed.

Q13. What is a vernier height gauge used for?

A vernier height gauge transfers vertical dimensions from a surface plate reference. It is used for layout, step heights, locating hole centers, and checking heights from a datum plane.

Q14. What is the cosine error in measurement?

Cosine error appears when the measurement axis is not aligned with the true dimension. Even a small angle creates under-reading, which is why the squareness of contact and seating is a real quality lever.

Micrometer Screw Gauge

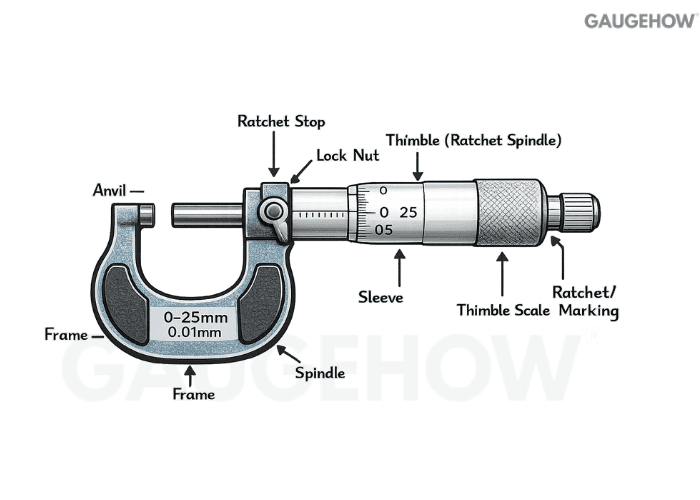

Q15. What is the least count of a micrometer screw gauge?

Least count equals pitch divided by the number of thimble divisions.

Many metric micrometers use a 0.5 mm pitch and 50 divisions, giving a 0.01 mm least count.

Q16. What is the pitch of a micrometer?

Pitch is the axial travel of the spindle for one full rotation. Pitch quality and thread condition decide smoothness, and poor threads quietly destroy trust in tight tolerance checks.

Q17. Why ratchet stop used in a micrometer?

The ratchet controls measuring force so the operator's hand pressure does not bend the frame or compress the part surface. Uniform force improves the same-setup variation immediately.

Q18. What is backlash in micrometers, and how can it?

Backlash is lost motion due to clearance in the screw. Always approach the final contact from the same direction and use the ratchet for the last few clicks.

Q19. How to check zero error in a micrometer?

Clean faces, close using the ratchet, and confirm the reading at zero. If it is off, correct per procedure or quarantine the tool based on your calibration rules.

Q20. why temperature affect micrometer reading?

The frame and part expand with heat. Hand heat alone can shift tight readings. Use insulated grips, minimize holding time, and let parts stabilize near 20 °C when tolerances are small.

Q21. How to measure a thin sheet with a micrometer without error?

Use the ratchet only, avoid over-tightening, and consider proper anvils for delicate surfaces. For very soft materials, a thickness gauge with defined contact pressure can reduce force distortion.

Q22. How to correct the micrometer reading with zero error?

If the micrometer reads +0.01 mm when fully closed, subtract 0.01 mm from observed values.

Example: Observed shaft diameter is 12.48 mm, corrected value becomes 12.47 mm.

Gauge Blocks, Comparators, And Limit Gauges

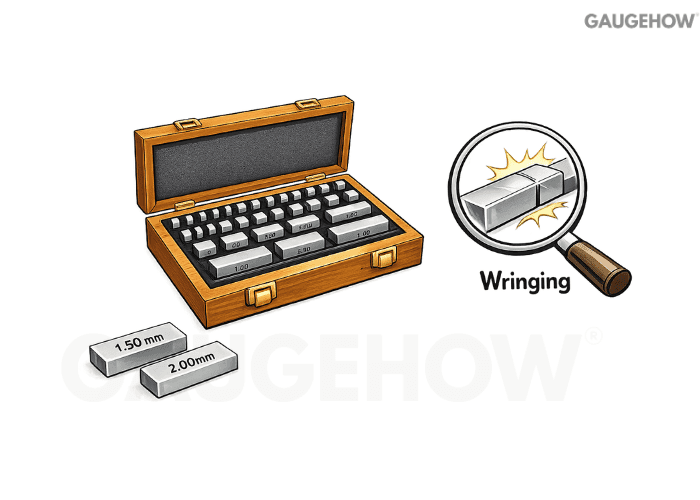

Q23. What are gauge blocks?

Gauge blocks are precision length standards used to set, verify, and calibrate instruments. They are the backbone of dimensional traceability in real inspection systems.

Q24. What is the wringing of gauge blocks?

Wringing is the controlled sliding adhesion of two clean gauge blocks so they stick with minimal air gap.

Poor wringing adds tiny length errors that show up as “mystery drift” later.

Q25. How to select gauge blocks to make a size?

Use the minimum number of blocks to reach the target length, clean faces, then wring using a gentle sliding motion. Fewer blocks reduce handling error and thermal pickup.

Q26. What is a comparator in metrology?

A comparator measures deviation from a master rather than absolute size. It is often better than direct measurement when tolerance is tight, and you need speed with high repeatability.

Q27. What is a dial indicator used for?

Dial indicators track variation such as runout, flatness trend, and concentricity behavior while rotating or sliding. Their strength is detecting change, not producing an absolute dimension report.

Q28. What is a go/no-go gauge?

A GO/NO-GO gauge gives a fast accept or reject at the limit size. It is ideal for high-volume checks when the decision matters more than a detailed measurement value.

Q29. How to set the sine bar using gauge blocks?

Use height = L × sin(θ).

Example: With a 150 mm sine bar and 17°, sin(17°) ≈ 0.292, so height ≈ 150 × 0.292 = 43.8 mm gauge block stack, then verify stable seating before checking the part angle.

CMM And Advanced Metrology

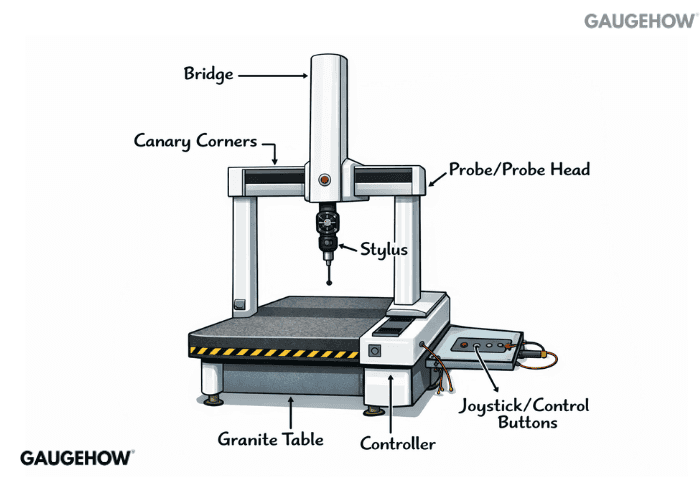

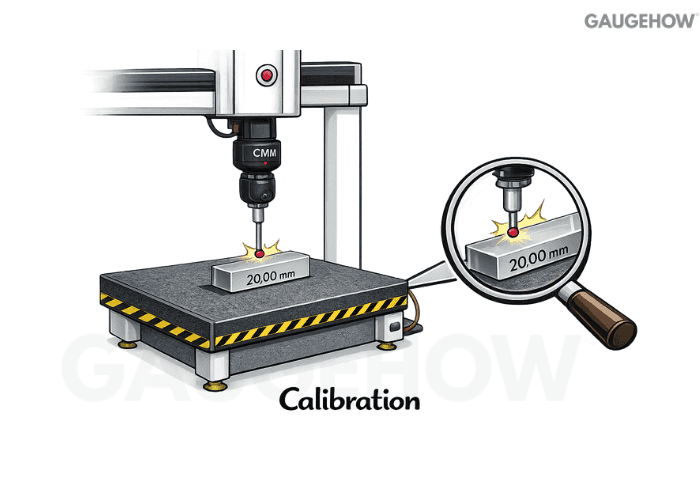

Q30. What is CMM?

A CMM measures 3D coordinates using a probe and calculates sizes and GD&T features from those points. It is powerful because it measures geometry relative to datums, not isolated dimensions.

Q31. What is touch trigger probing and scanning in CMM?

Touch probing collects discrete points and fits basic features. Scanning collects many points and represents form and freeform surfaces better, especially when profile control matters.

Q32. What is alignment in CMM, and why is it important?

Alignment sets the coordinate system and datums. If the datum setup is wrong, every reported result becomes consistently wrong, even with a perfect machine.

Q33. What are common CMM errors?

Bad fixturing, temperature drift, weak probing strategy, incorrect datum order, and dirty stylus tips cause most errors. Most “CMM problems” are method problems.

Calibration, Uncertainty, And MSA

Q34. What is calibration, and what is verification?

Calibration establishes thinstrument'snt relation to a reference and records results with uncertainty.

Verification checks whether the instrument meets a requirement, usually passes or fails.

Q35. What is ISO/IEC 17025 in calibration?

ISO/IEC 17025 focuses on competence, controlled methods, traceability, and stated uncertainty so calibration results are defensible. Even outside a lab, its logic is what audits expect.

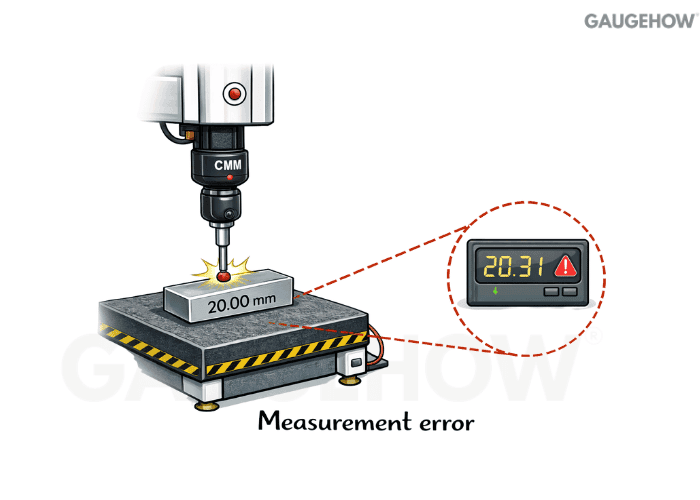

Q36. What is measurement uncertainty?

Uncertainty is the believable range around your measured value.

Example: You measure a bore at 20.006 mm with uncertainty ±0.004 mm. If the upper limit is 20.010 mm, the overlap means your decision is close, so method control and decision rule matter more than arguing over the last micron.

Q37. What is guard banding in quality inspection?

Guard banding tightens the acceptance zone to protect against uncertainty near tolerance edges. If tolerance is 20.000 to 20.010 mm and uncertainty is ±0.004 mm, you may accept only up to 20.006 mm to avoid accepting a true value that could exceed 20.010 mm. This prevents borderline escapes when measurement overlap exists.

Q38. What is GRR in MSA?

GR&R quantifies how much variation comes from the measurement system itself, combining repeatability and reproducibility. It tells you whether the gauge is good enough to control the process you are using it on.

Q39. What is an acceptable gage R&R percentage?

As a practical rule relative to tolerance, under 10% is good, 10% to 30% is usable depending on risk, and over 30% is not usable for control. If it is high, reduce operator variation first, then improve fixturing, then upgrade the gauge or the method.

Q40What does ISO 9001 require for measuring equipment calibration?

ISO 9001 expects measuring resources to be controlled so results are valid for product conformity. That means defined calibration or verification intervals, clear status identification, protected handling, retained records, and action when equipment is found out of tolerance, including impact review on past inspection results.

Conclusion

Strong inspection is not about chasing decimals. It is about choosing the right instrument for the tolerance, controlling the method, and knowing when the measurement itself is the risk.

If you can read verniers and micrometers cleanly, build traceable setups with gauge blocks, align CMM datums correctly, and apply uncertainty logic near limits, your quality decisions become consistent, auditable, and hard to challenge.