What Is CFD? Computational Fluid Dynamics Explained Simply

Dec 29, 2025

Deepak S Choudhary

🔧 Trusted by 23,000+ Happy Learners

Learn CAE & Simulation Tools

Learn the CAE tools engineers actually use: ANSYS, OpenFOAM, Abaqus, COMSOL & MATLAB -Start your journey here

If you are staring at velocity contours right now, and they look “nice,” but you still feel unsure, you are not alone. Most CFD confusion comes from one gap. You see the picture, but you do not yet know what to trust. And once a deadline is near, that doubt grows fast, because your manager will ask the same thing every time, which is basically “why should I believe this result?”

This guide is built for that exact desk moment. You will learn "what is CFD". What it solves, and why the workflow matters more than the software. Then you will walk through how a CFD simulation is actually built, step by step, with the checks that prevent false confidence. You will also see the common mistakes that quietly break a CFD analysis, so you can spot them early rather than after a week of computing.

By the end, you will have a simple mental model, a credibility ladder you can reuse, and one small copyable example that shows how accuracy improves with mesh refinement. And to be honest, that combination is what makes CFD feel predictable, rather than mysterious.

What Is CFD And What Does It Actually Do

Use CFD to predict flow and heat behavior on a computer; it does this by enforcing conservation of mass, momentum, and energy fields numerically directly.

That sounds heavy, but the idea is simple. Instead of guessing how air or water moves, you ask the computer to calculate it, using physics plus a lot of small approximations.

CFD is worth defining by the decisions it supports: forces, pressure loss, heat rate, mixing, and distribution, before the metal is cut. It works because the equations are solved, then checked against a target KPI tolerance.

In practice, you use it to compare designs, reduce prototypes, and understand “why” a performance issue exists.

A quick note that matters. CFD does not create truth from nothing. It turns your inputs into an answer. So if the inputs are wrong, the answer can still look smooth. That is why good CFD is less about pretty plots and more about controlled assumptions.

What Does CFD Stand For

CFD is short for Computational Fluid Dynamics, a fluid mechanics discipline that uses numerical schemes and data structures to compute flow fields on digital machines reliably.

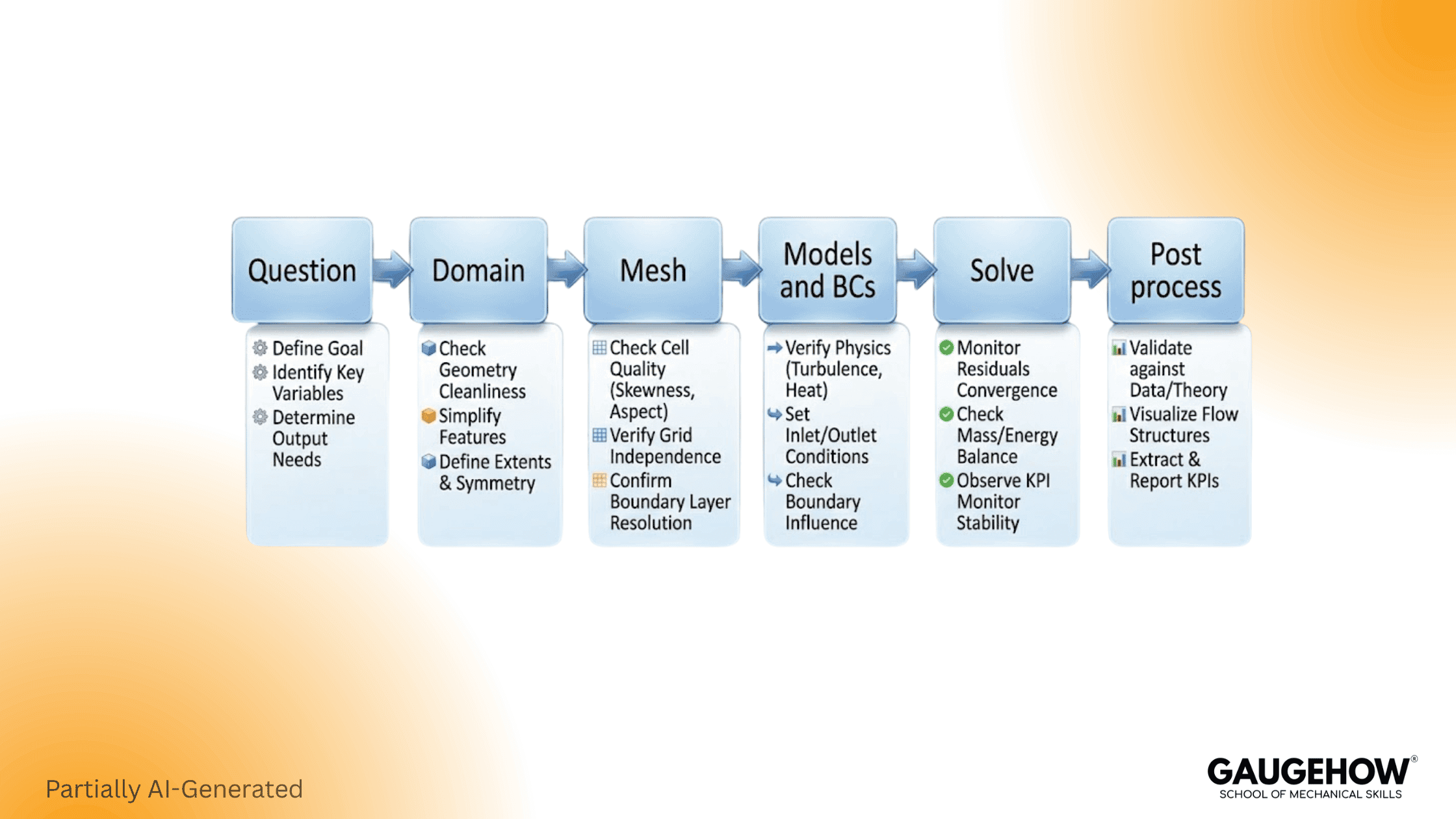

How A CFD Simulation Works Step By Step

Most first-page explainers show a recipe, yet skip the verification that prevents confident errors. This guide keeps the step order and pairs each stage with checks, since the same CFD workflow repeats across tools and industries today.

Step 1: Define The Question, Not Just The Geometry

Start with the output you actually need. Is it pressure drop, drag, temperature rise, or flow split? Write one KPI on top of your run log. If you skip this, you will chase plots, and you will lose time.

Also, set the operating point. You need the flow rate, inlet temperature, density model, and expected regime. Compressible or incompressible is not a taste choice. It is a physics choice.

Step 2: Build A Domain That Lets The Flow Develop

Most beginners cut the domain too tightly. Then the inlet and outlet control the answer. You want the boundaries to be “far enough” that they do not force unphysical gradients.

For internal flows, you generally need enough straight length for profiles to form. For external aero, you need enough space so the wake fits. The exact number depends on the case, but the principle stays the same. Boundaries should not fight the physics.

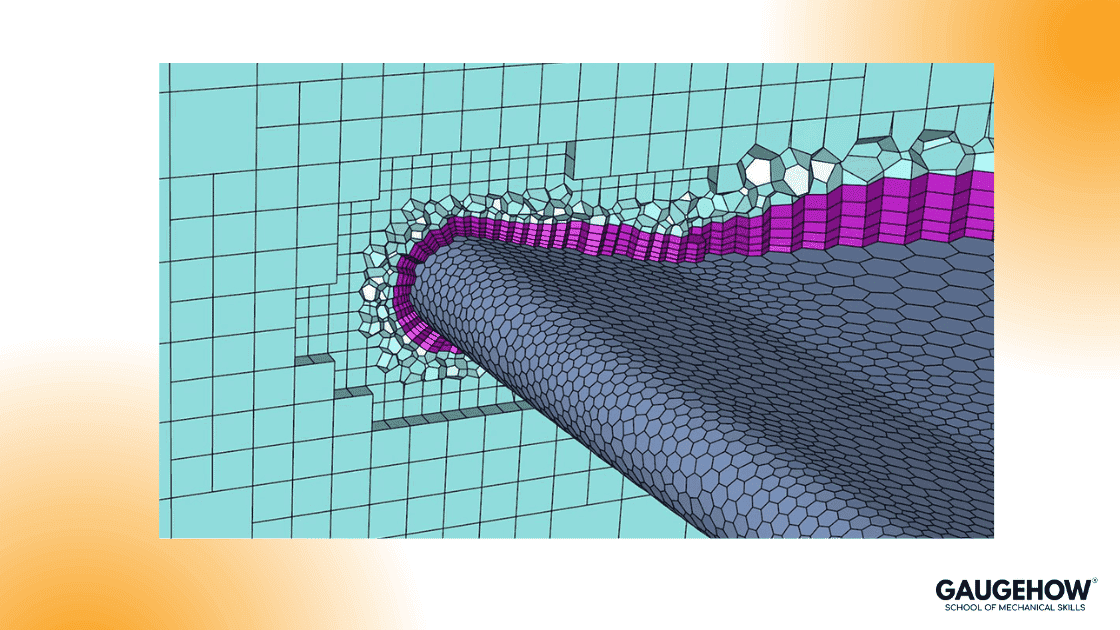

Step 3: Mesh The Domain, Because The Mesh Is The Model

A CFD solver does not solve the continuous world. It solves your discrete mesh. Wikipedia’s methodology summary is blunt about this, and it is correct.

You discretize the flow domain into cells, then solve the conservation equations on each cell.

So your mesh choices matter more than many people admit. You want good quality, enough near-wall resolution, and controlled refinement where gradients live. Do not refine randomly. Refine where the physics changes fast.

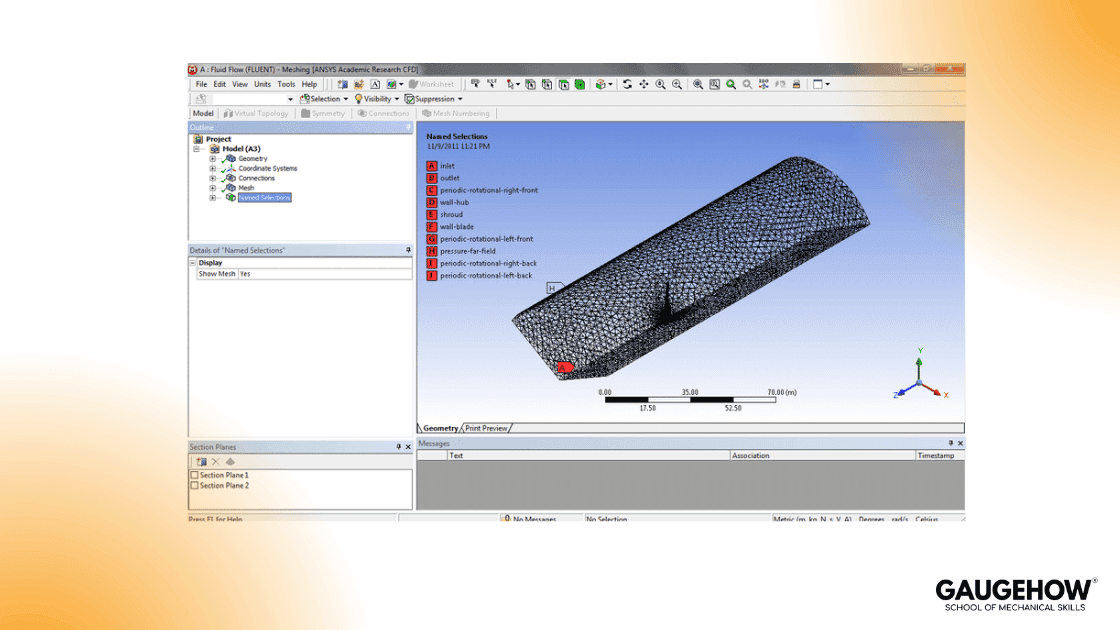

Step 4: Choose Models And Boundary Conditions With Intention

This is where many CFD analysis problems are born. A turbulence model is not a “better or worse” switch. It is an assumption about unresolved motion. If the flow is laminar, do not force turbulence.

Boundary conditions are the other major risk. Inlet mass flow, inlet velocity profile, outlet pressure, wall roughness, and thermal conditions all affect results. If the boundary condition is guessed, the output is guessed too, even if the solver converges.

Step 5: Solve, But Monitor The Right Signals

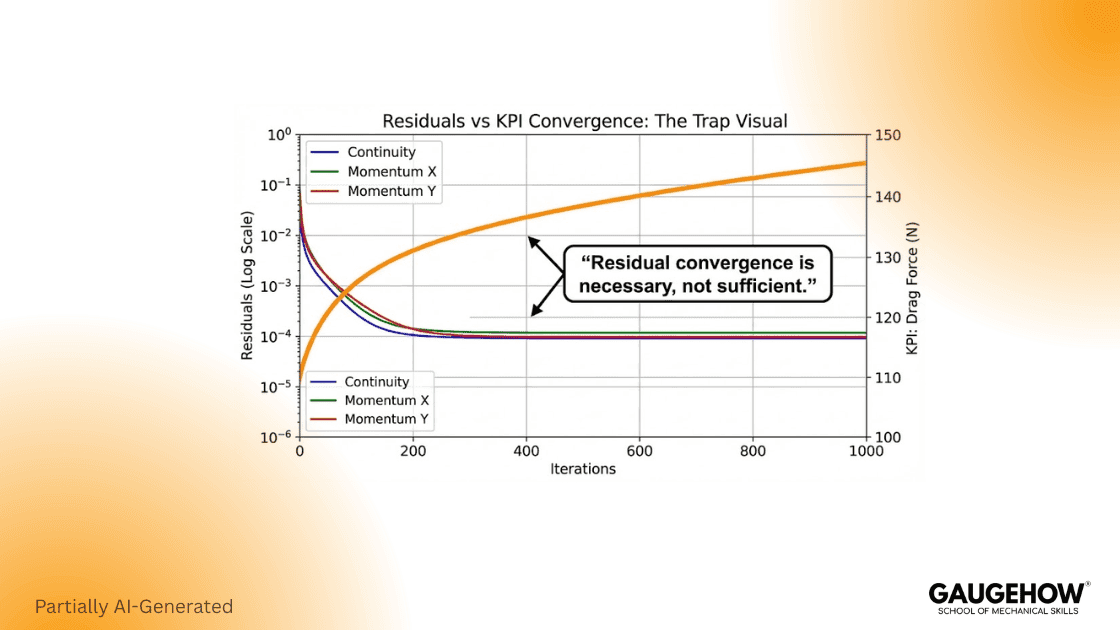

Many people watch residuals only.

Residuals are useful, but they are not the final truth. A converged residual can still hide a drifting force coefficient or a mass imbalance.

Call a run converged only when the KPI stabilizes and global balances close; residuals alone mislead. Track histories and mass-energy error, and require under 1% imbalance per step consistently.

Step 6: Post Process Without Fooling Yourself

Post-processing is where confidence gets built or destroyed. Always start with sanity checks. Does flow direction make sense? The pressures are within expected ranges. Does the pressure drop sign match the driving direction?

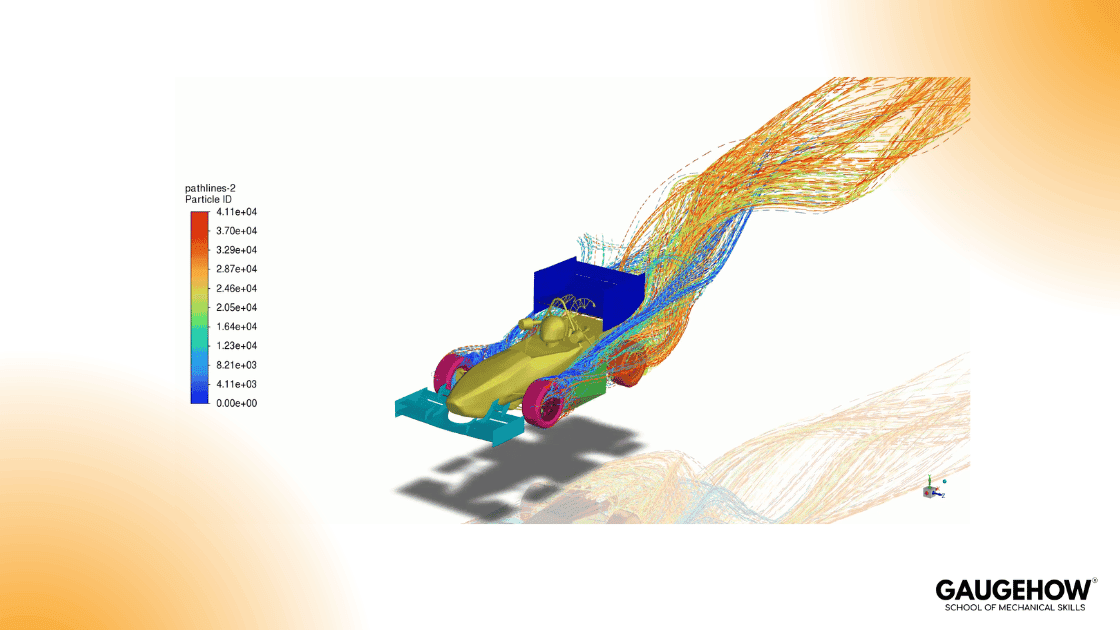

Only after that, use contours and streamlines to understand the story. Contours are great for insight, but they are not proof.

The Physics Behind CFD, Without The Math Wall

You do not need to memorize the equations to use CFD well. You do need to know what they enforce.

Conservation Laws Are The Core

CFD is built around conservation of mass, momentum, and energy. (Ansys)

Mass conservation keeps the flow from magically appearing. Momentum conservation captures acceleration and pressure forces. Energy conservation handles heat transfer and temperature change.

These laws are often expressed through Navier Stokes equations. Those equations describe how velocity and pressure evolve in space and time. (Wikipedia)

Discretization Is The Key Approximation

The governing laws live in continuous space, but your model does not. CFD turns derivatives into solvable algebra over control volumes or nodes, using schemes like finite volume, finite element, or finite difference.

This matters because discretization creates error. If your mesh is coarse, gradients smear. If your time step is large, unsteady motion can be distorted. That is why mesh refinement and time step sensitivity exist.

What Controls Accuracy In A CFD Analysis

Accuracy is not one thing. It is a stack of errors, and each layer can dominate.

1) Boundary Conditions Can Dominate Everything

If you do not know the inlet turbulence level, or you guess an outlet pressure, that uncertainty goes straight into the result. You can build a perfect mesh and still get a wrong answer.

So in practice, you treat boundary conditions like measured inputs. If you cannot measure them, you bracket them. Run the best case and the worst case.

2) Turbulence Modeling Is A Controlled Compromise

Most engineering flows are turbulent, and turbulence contains many scales. You cannot resolve them all for real products, at least not usually. So you model the effect of small scales.

That is why RANS models are common in industry, and why LES is used when unsteady structures matter more, but at a higher cost. If your flow separates strongly or has sa trong swirl, model choice matters even more.

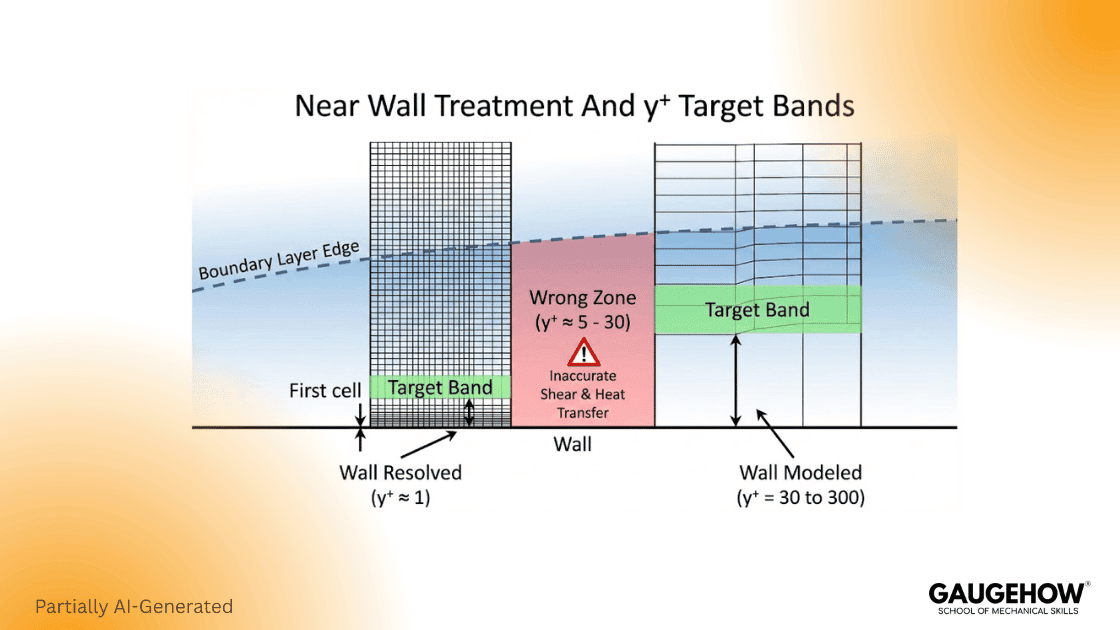

3) Near Wall Treatment And y Plus Can Make Or Break You

Walls are where shear and heat transfer happen, so wall treatment is critical. One practical way to think about it is y plus, which measures how far your first cell is from the wall in wall units.

Do not confuse numerical settling with physical truth. A case can “converge” and still be wrong because the mesh, turbulence model, or boundary setup biases the physics; treat mesh sensitivity as a required gate and track KPI drift between refinements.

If you ignore this, you can get “converged” answers with wrong friction and wrong heat transfer. That error then propagates into drag, pressure drop, and temperatures.

4) Convergence Is Not The Same As Correctness

This point is easy to miss, and it matters a lot. A solution can converge numerically and still be wrong physically. SimScale’s material on convergence and mesh sensitivity is aligned with this idea, because they separate “converged changes” from “accurate changes.” (SimScale)

So treat convergence as a gate, not a victory. You still need mesh sensitivity and validation logic.

Common Mistakes We See That Quietly Break Results

This is the section most competitors keep generic, but to be honest, this is where trust is earned. Here are the mistakes that show up again and again, across tools.

Using an outlet too close to the separation, so the wake is forced.

Copying turbulence settings without matching the physics.

Refining the mesh everywhere, rather than at gradients.

Ignoring y plus ranges, so wall shear is wrong.

Trusting residuals while forces still drift.

Comparing two designs with different mesh quality.

Skipping mesh sensitivity, then quoting absolute numbers.

If you fix only one habit, fix this. Always connect your settings to the question. CFD is not just “run the solver.” It is “run the right model for the KPI.”

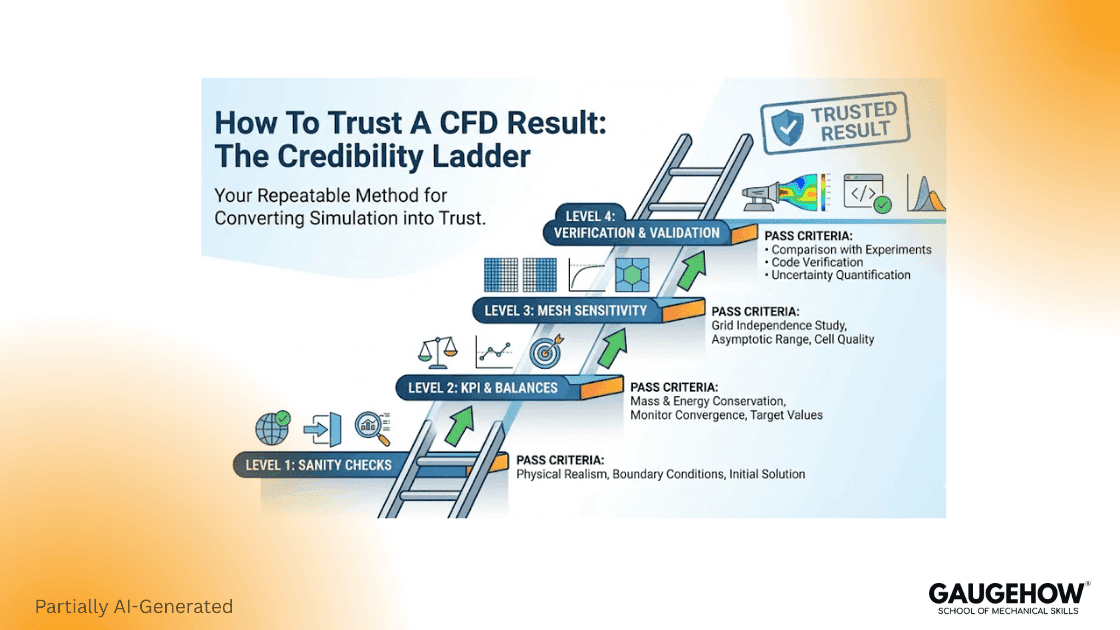

How To Trust A CFD Result: The Credibility Ladder

This is the unique section that most page one pages do not operationalize. You can use this ladder on any CFD simulation, and you can defend it calmly.

Level 1: Sanity Checks In 10 Minutes

Start with the basics. Check mass conservation, units, boundary direction, and energy balance if thermal. Look for impossible values, like negative density in incompressible flow, or supersonic pockets in a low-speed duct.

Then check your KPI trend. If you run steady state, your KPI should settle. If it does not settle, you do not have a stable answer yet.

Level 2: Convergence With The Right Metrics

Use residuals as an early indicator, not as the acceptance test. Close the global balances and watch the engineering KPI history, and set a stop rule like <1% mass imbalance with a stable KPI window before you trust the plots.

If the residuals drop, but the KPI keeps drifting, your case is not ready.

Level 3: Mesh Sensitivity Or Mesh Independence

A mesh sensitivity study means running the same case on different mesh resolutions and watching how the converged solution changes. (SimScale)

If the KPI changes a lot, your mesh is still part of the answer.

NASA’s verification and validation tutorial emphasizes grid convergence thinking, and it even gives practical safety factor guidance for grid comparisons. (grc.nasa.gov)

Here is a simple, practical rule from NASA’s spatial convergence guidance.

If you compare only two meshes, use a conservative safety factor of around 3.

If you compare three or more meshes, a smaller factor like 1.25 is often used.

You do not need to turn this into heavy math on day one. You do need to show that refinement stops changing the KPI.

Level 4: Verification And Validation, Not Just Confidence

Verification asks, “Did I solve the equations right?” Validation asks, “Do the equations and models match reality?”

ASME V and V 20 are built around quantifying accuracy by comparing simulation and data at defined points, while considering uncertainty in both. (ASME) NASA’s V and V tutorial also frames verification and validation as a structured process, not a vibe check. (grc.nasa.gov)

In practice, you validate trends first. If you can compare against a benchmark, a datasheet curve, or a simple experiment, do it. If you cannot, at least compare against a known limit case.

Mini Example You Can Copy: Laminar Pipe Pressure Drop

Most competitors explain CFD, but they do not show a reproducible “trust build” example. So let us do one that you can verify with an equation, and that is why it is powerful.

The Setup

You model incompressible laminar flow in a smooth circular pipe.

Choose these example inputs:

Pipe diameter D = 0.02 m

Pipe length L = 1.0 m

Fluid is water at room temperature, so viscosity is known

Mean velocity U = 0.2 m/s

For fully developed laminar flow, the pressure drop has a known analytical form. That gives you a truth target, so you can test mesh and solver behavior.

What You Track

Your KPI is the pressure drop ΔP between two planes. Then you run three meshes, coarse, medium, and fine, and you compare ΔP.

Example Mesh Sensitivity Table

Below is a realistic pattern you should expect. The exact values depend on the setup, but the behavior is the key.

Mesh Level | Cell Count | ΔP (Pa) | Change Vs Previous |

Coarse | 120k | 248 | – |

Medium | 420k | 256 | +3.2% |

Fine | 1.4M | 259 | +1.2% |

If your ΔP changes 10% between medium and fine, you are not done. If it changes around 1% and trends stabilize, you are close.

Now add one more sanity check. The velocity profile should look parabolic in laminar flow. If it does not, your inlet development length, mesh, or numerics are interfering.

Why This Example Matters

This simple pipe case teaches three deep habits.

First, a KPI is defined before you run. Second, mesh refinement is tied to the KPI, not to visuals. Third, validation is possible because physics has a known solution.

Once you can do this well, you can scale the same habits to bends, manifolds, and heat exchangers.

CFD Vs Wind Tunnel Vs Hand Calculations

A good engineer does not “always CFD.” A good engineer chooses the right tool.

When CFD Is The Best First Tool

Use CFD when geometry is complex, when you need flow distribution, or when experiments are slow. It is also great for comparing design variants quickly, as long as inputs stay consistent.

CFD is especially strong for relative comparisons. If you want to know if Design B is better than Design A, CFD can be very effective, even when absolute accuracy is hard.

When Hand Calculations Are Better

Use hand calculations when the flow is simple and the uncertainty tolerance is high. Darcy Weisbach for pressure drop, simple heat transfer correlations, and momentum balances are fast and robust.

Hand calculations also act as guards. They tell you if CFD is wildly off, and that matters.

When Experiments Or Wind Tunnels Matter Most

Experiments are still the anchor for validation. Wikipedia notes that CFD software is commonly validated with experiments such as wind tunnels, and that is still the standard practice. (Wikipedia)

So if the decision is high risk, or if the flow regime is tricky, experiments are the strongest truth source. CFD then becomes a way to understand and generalize those measurements.

Tools And Software: What Matters More Than The Brand

People often ask which tool to learn first. To be honest, software matters less than method.

Most modern solvers share the same core pieces:

Geometry and meshing tools

A solver for the governing equations

Turbulence and heat transfer models

Post-processing for fields and derived metrics

You will see commercial tools like ANSYS Fluent and open source tools like OpenFOAM. The best choice depends on your budget, industry norms, and support needs.

More Complete Guide on Software Selection:- Best CFD Software 2026: Commercial Vs Open Source Guide

What matters most is whether you can do the credibility ladder on your results. If you cannot, the brand name will not save you.

Best Practices That Keep CFD Honest

This is a high-impact section, so we will use bullets once more, but keep it tight.

Define one KPI before you mesh.

Keep boundary conditions measurable or bracketed.

Set y plus based on the wall model you are using.

Track mass imbalance and your KPI, not residual curves alone.

Prove mesh independence on the KPI with a sensitivity sweep.

Check the trend against a trusted reference and log the error band.

If you follow those six, your CFD analysis becomes defensible.

Frequently Asked Questions

What Is CFD In Simple Words

CFD is a way to predict fluid flow on a computer. It solves the physics equations on a mesh, so you can estimate pressure, velocity, and temperature.

Is A CFD Simulation Always Accurate

No, and that is normal. Accuracy depends on boundary conditions, mesh, turbulence modeling, and validation checks, not just solver convergence.

What Is The Difference Between CFD Simulation And CFD Analysis

A CFD simulation is the run itself, meaning setup plus solve. A CFD analysis is the full decision process, meaning assumptions, checks, sensitivity, and validation logic.

What Does CFD Stand For

It stands for Computational Fluid Dynamics.

Why Do Two CFD Runs Give Different Answers

They often differ because the mesh or boundary conditions changed, even slightly. Turbulence model choices, wall treatment, and numerics can also shift results.

What Is Mesh Independence

It means your KPI does not change much with refinement. A mesh sensitivity study is the standard way to test that.

What y Plus Should I Target?

If you fully resolve the wall region, aim for y plus below about 1. If you use wall models, typical guidance is y plus between about 30 and 300.

Conclusion

Once you understand what CFD is, the next step is to treat it like engineering, not like art. CFD is physics solved on your mesh, so your inputs, your wall strategy, and your sensitivity checks decide how much trust you can claim.

If you want one practical next move, do this. Pick one KPI, run a simple mesh sensitivity study, and then explain your result using the credibility ladder. That is how CFD stops feeling uncertain and starts feeling controlled.

Also Read:- Real-world applications of CFD: Simulation & Analysis 2026

Our Courses

Complete Course Library

Access to 40+ courses covering various fields like Design, Simulation, Quality, Manufacturing, Robotics, and more.